- This topic is empty.

-

AuthorPosts

-

2025-09-11 at 6:15 pm #10633

On-Site Flange Facing Success Case: MT Portable Machine Supports KOBELCO in Compressor Industry

In the compressor industry, reliability and precision are essential. KOBELCO (Kobelco Wuxi Compressor Co., Ltd.), a leading manufacturer of centrifugal compressors, recently faced a critical challenge during the maintenance of a centrifugal compressor casing. The sealing surfaces of the volute casing flange had become worn and scarred due to long-term operation under high pressure and temperature conditions. Such damage, if not resolved, could lead to leakage, reduced efficiency, and costly downtime.

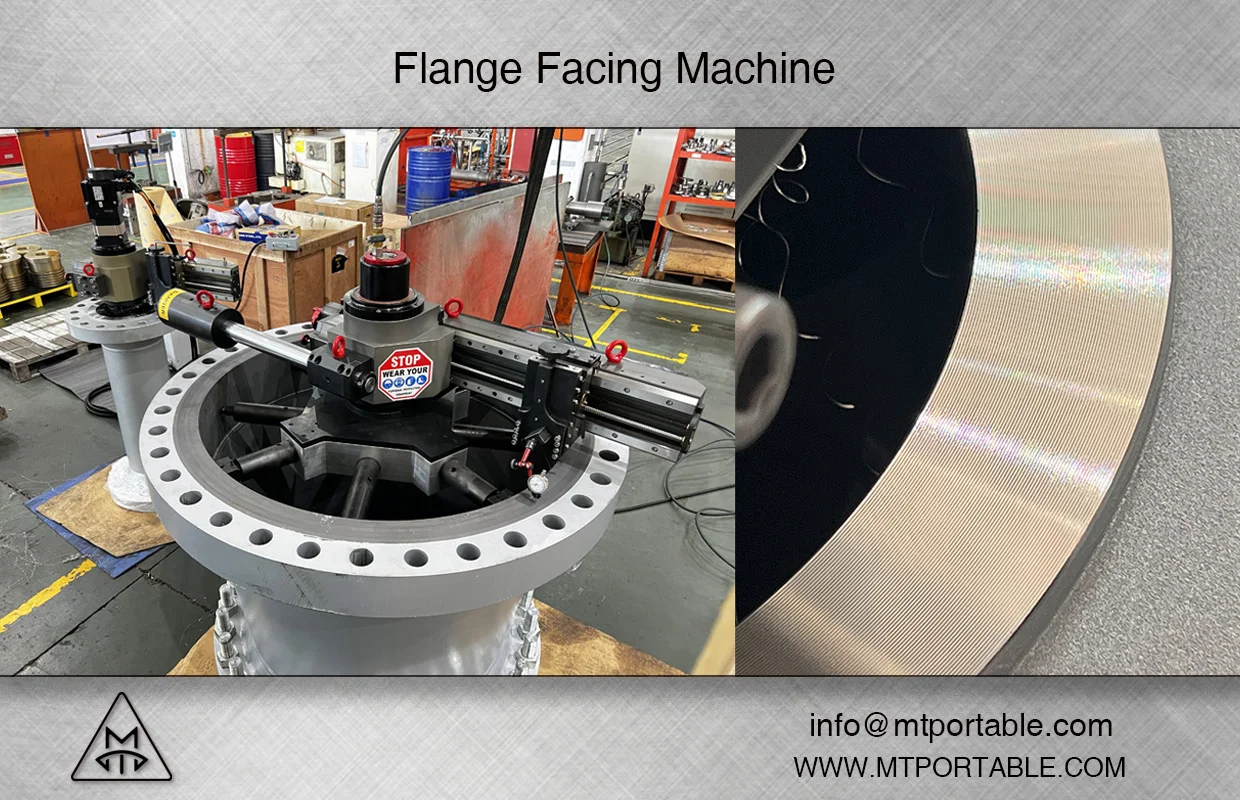

To ensure the integrity of the flange sealing surface, KOBELCO invited the MT Portable Machine team to provide on-site machining solutions. After detailed technical assessment, the MT team deployed two advanced flange facing machines: the FI40E Flange Facing Machine (Electric Servo Motor) and the FI60P Flange Facing Machine (Pneumatic Motor). Both models are internally mounted flange facers designed for precision reconditioning of large-diameter flange gasket surfaces in demanding industrial environments.

The FI40E Flange Facing Machine, with a working range of 153–1000 mm, was utilized to restore the smaller flange faces of the compressor assembly. Powered by a Panasonic servo motor, it allowed precise speed control (0–40 rpm) and stable cutting performance. Its NSK high-precision bearings and “V” linear guide ensured superior accuracy, while the six continuous feed settings achieved the required ASME B16.5 gramophone finish, critical for flange sealing reliability.

For the larger volute casing flanges, the MT team operated the FI60P Flange Facing Machine, offering a wide facing range of 320–1500 mm. Driven by a high-performance Modec pneumatic motor (4.1 Hp / 3.0 kW), the FI60P delivered reliable torque and smooth rotation, even under heavy cutting loads. With six automatic groove-facing and boring feed settings, it efficiently removed corrosion, repaired welding defects, and restored the sealing surface to like-new condition.

Throughout the operation, MT Portable Machine’s engineering team demonstrated exceptional professionalism and rapid response capability. Prior to dispatch, both machines had undergone rigorous factory acceptance testing to ensure safety and performance standards. On-site, the modular design and compact structure of the flange facers allowed the team to complete installation and alignment quickly, minimizing downtime for KOBELCO’s production line.

This successful project once again validated the trust of world-renowned enterprises in MT Portable Machine’s technology. By providing precise, efficient, and portable flange facing solutions, the MT team not only resolved KOBELCO’s immediate problem but also reinforced long-term operational reliability for their centrifugal compressors.

MT Portable Machine continues to be a reliable partner for the oil & gas, power, chemical, and compressor industries, delivering robust flange facing machines and professional on-site machining services that comply with international ASME standards.

If you encounter flange surface damage, leakage issues, or require technical consultation for on-site machining challenges, please contact the MT Portable Machine technical team at info@mtportable.com to receive the latest product parameters and customized solutions.

http://www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd -

AuthorPosts

- You must be logged in to reply to this topic.