- This topic is empty.

-

AuthorPosts

-

2025-11-19 at 1:52 pm #11206

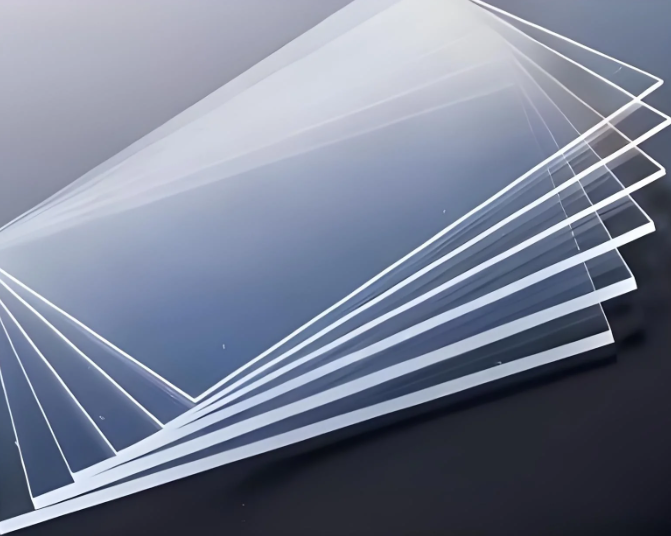

In the competitive world of visual merchandising, retail display, and signage, clarity, durability, and aesthetic appeal are non-negotiable. Whether it’s a POP display in a retail store, a transparent shelving system, or high-end advertising signage, the performance of the material directly impacts the overall quality and longevity of the product. Ubest’s extrusion-grade PETG resin, particularly the UB-104 grade, has emerged as a leading solution for producing clear, robust, and long-lasting sheets, fulfilling the demanding needs of modern applications.

PETG Resin Performance: Clarity Meets Durability

1. Optical Properties

One of the defining characteristics of Ubest PETG resin is its exceptional transparency:

-

High Light Transmittance: PETG sheets maintain clarity above 90%, ensuring sharp visibility of signage graphics and POP designs.

-

Low Haze: Minimal distortion allows for premium-looking displays that catch consumer attention.

-

UV Resistance: With proper stabilization, PETG resists yellowing over time, maintaining visual appeal even under prolonged sunlight exposure.

These properties make UB-104 PETG sheets thicker than 2mm ideal for applications requiring both structural integrity and crystal-clear aesthetics.

2. Mechanical Strength

Durability is crucial for commercial displays and furniture applications. UB-104 PETG resin provides:

-

Impact Resistance: Superior toughness compared to acrylic sheets, reducing breakage during handling or transportation.

-

Flexural Strength: Adequate rigidity to support shelving units, standees, and architectural partitions without sagging.

-

Scratch Resistance: Optimized processing reduces surface abrasions, maintaining a polished look throughout its lifecycle.

This combination of clarity and mechanical strength ensures that PETG sheets withstand both operational stress and environmental factors.

Extrusion Process Optimization for Sheet Production

The extrusion process plays a vital role in achieving both clarity and durability in PETG sheets. Ubest has optimized its UB-104 resin specifically for high-performance extrusion:

-

Temperature Control:

-

Precise control of melt temperature ensures uniform viscosity and prevents bubble formation.

-

Avoids polymer degradation that can compromise optical clarity and surface finish.

-

Cooling and Roll Surface Optimization:

-

Controlled cooling maintains flatness and reduces internal stresses that can lead to warping.

-

Polished roll surfaces prevent surface blemishes and ensure a smooth, glossy finish.

-

Additive Compatibility:

-

UB-104 integrates well with impact modifiers, anti-UV stabilizers, and flame retardants, enhancing sheet performance without sacrificing transparency.

-

Compatible with co-extrusion and lamination processes for multi-layered applications.

-

Thickness Uniformity:

-

High precision extrusion ensures consistent sheet thickness, essential for POP displays and architectural applications requiring seamless alignment.

Key Applications of Ubest PETG Sheets

PETG sheets are versatile and serve multiple high-performance applications across industries:

1. Retail Signage and POP Displays

-

Point-of-Purchase Displays: Clear and durable PETG sheets present products attractively while ensuring structural integrity under frequent handling.

-

Advertising Signs: High optical clarity ensures logos and promotional graphics are vibrant and easily readable.

-

Indoor and Semi-Outdoor Use: UV-stabilized PETG maintains visual quality even with exposure to sunlight or fluorescent lighting.

2. Shelving and Fixtures

-

Transparent Shelving: PETG’s strength allows for freestanding shelves and multi-tiered display units without sagging.

-

Modular Furniture Components: Ideal for contemporary furniture, partitions, and display racks where both aesthetic appeal and durability are critical.

-

Easy Cleaning: Smooth surfaces resist dust accumulation and allow for simple maintenance.

3. Composite Material Applications

UB-104 PETG resin exhibits excellent compatibility with other polymers, including:

-

GAG (Glass-filled Acrylic-Grade): Enables hybrid sheets with enhanced mechanical performance.

-

A-PET: Facilitates multi-layered structures for improved strength and chemical resistance.

-

Custom Lamination: For specialized applications requiring scratch resistance, anti-glare, or colored layers.

This compatibility allows manufacturers to create innovative multi-functional displays without compromising transparency or structural integrity.

Sustainability and Eco-Friendly Considerations

Ubest emphasizes sustainable production practices and eco-friendly materials:

-

Low Environmental Impact: PETG sheets are fully recyclable and reduce reliance on more energy-intensive plastics like acrylic or polycarbonate.

-

Chemical Stability: No harmful emissions during extrusion and processing.

-

Long Lifespan: Durable PETG sheets reduce replacement frequency, minimizing material waste in retail and construction environments.

These factors align with the global trend toward green materials and sustainable retail practices, allowing brands to maintain a responsible environmental footprint.

Supply Chain Reliability

Consistency in material supply is critical for manufacturers relying on PETG sheets:

-

Annual Production Capacity of 100,000 Tons: Ubest ensures a stable and scalable supply for both small and large-scale projects.

-

Global Distribution: Serving markets in China, Southeast Asia, India, Europe, and the United States.

-

Technical Support: In-house R&D provides guidance for extrusion optimization, composite integration, and product customization.

This reliability allows clients to plan large production runs without risk of material shortages or quality variations.

Practical Tips for Manufacturers Using UB-104 PETG

-

Sheet Thickness Management: Maintain consistent thickness over 2mm for structural applications.

-

Temperature Optimization: Avoid overheating during extrusion to prevent polymer discoloration.

-

Stabilizers Integration: Consider UV and impact modifiers for long-term outdoor signage.

-

Surface Finishing: Use polished rolls or calendering to achieve a smooth and reflective sheet surface.

-

Compatibility Testing: Pre-test composite applications with GAG or A-PET to ensure lamination adhesion and transparency retention.

FAQ: Ubest Extrusion-Grade PETG Resin

Q1: What makes UB-104 PETG resin ideal for signage applications?

A1: High transparency, low haze, UV resistance, and excellent impact strength ensure signage remains clear and durable in indoor and semi-outdoor environments.Q2: Can UB-104 sheets be used for thicker applications?

A2: Yes. UB-104 supports sheet production above 2mm thickness while maintaining optical clarity and mechanical stability.Q3: Is PETG recyclable?

A3: Absolutely. PETG sheets are fully recyclable, contributing to sustainable manufacturing and reducing environmental impact.Q4: How does UB-104 perform in composite materials?

A4: UB-104 is compatible with A-PET, GAG, and co-extrusion applications, allowing multi-layered or reinforced sheet structures.Q5: How does Ubest ensure consistent quality?

A5: With an annual production capacity of 100,000 tons, strict QC, and in-house R&D, every batch meets optical, mechanical, and chemical performance standards.

Conclusion

For manufacturers seeking clear, durable, and high-performance sheets for signage, shelves, and POP displays, Ubest’s UB-104 PETG resin provides a comprehensive solution. Its combination of optical clarity, mechanical strength, extrusion-friendly properties, and sustainability makes it a top choice for global markets. By leveraging Ubest’s expertise, manufacturers can produce sheets that not only meet the technical demands of modern applications but also enhance visual appeal, improve durability, and optimize production efficiency.

From retail displays to composite sheet structures, UB-104 PETG ensures that your end products are vibrant, robust, and long-lasting, supporting profitability, design innovation, and sustainability across industries.

http://www.wxubest.com

Wuxi Ubest New Material Technology Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.