- This topic is empty.

-

AuthorPosts

-

2025-06-11 at 6:07 pm #9791

In the rapidly evolving landscape of industrial tire manufacturing, technological innovations continue to reshape the way tires are produced. One of the most significant advancements in recent years has been the development and widespread adoption of automatic tire building machines. In this blog post, as a high performance tire manufacturing machinery supplier, SONIWELL will share automatic tire building machine for industrial tire manufacturing, taking bias one stage tire building machine as an example.

Need for Automation in Tire Manufacturing

Tire manufacturing has traditionally been a labor-intensive process, involving multiple stages and a high degree of manual intervention. However, as the demand for industrial tires grows, driven by sectors such as agriculture, mining, and heavy machinery, manufacturers are increasingly seeking ways to streamline production, improve quality, and reduce costs. This is where automatic tire building machines come into play.

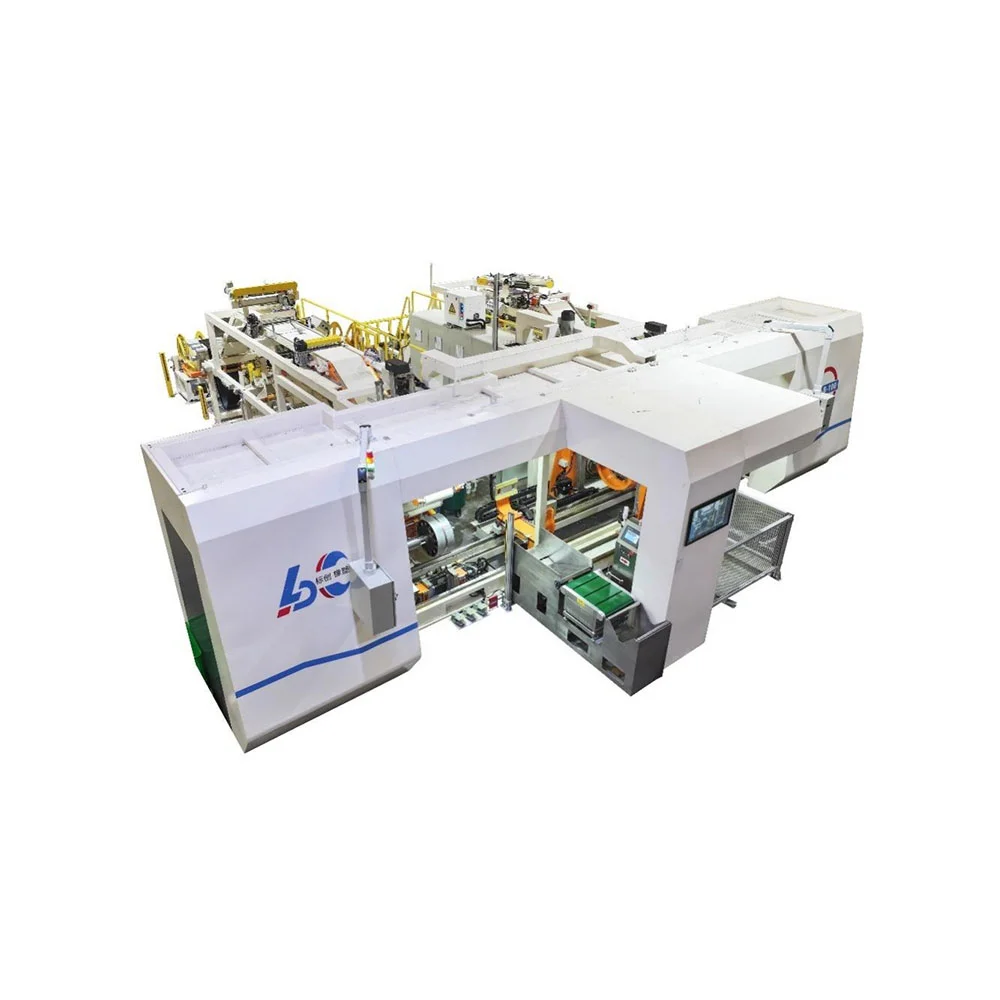

Introducing Automatic Bias One Stage Tire Building Machine

A prime example of this technological leap is the Automatic Bias One Stage Tire Building Machine offered by Soniwell Group. This machine represents a significant step forward in the automation of tire manufacturing processes. Designed to handle the complexities of industrial tire production, it integrates several advanced features that set it apart from traditional tire building methods.

Key Features of Automatic Bias One Stage Tire Building Machine

One-Step Production Process

One of the most notable features of this machine is its one-step production process. Unlike traditional multi-stage methods, this machine consolidates various steps into a single, seamless operation. This not only reduces the time required to produce each tire but also minimizes the potential for errors and inconsistencies that can arise from manual handling and multiple transitions between stages.

High Precision and Quality Control

The machine's integral welded mainframe ensures stability and durability, providing a solid foundation for precise operations. The ball-wrapped carcass drum, equipped with a vacuum suction port, is particularly suitable for tires without a liner, enhancing the machine's versatility. The use of a 2-stage servo conveyor feeding system further improves the accuracy of fixed length measurements, ensuring consistent quality across each layer of material.

In addition, the machine incorporates advanced detection systems that can identify and flag issues such as flash seams, wrong angles, big and small heads, and missing paste in the carcass joint. This level of quality control is critical in the production of industrial tires, where durability and reliability are paramount.

Advanced Cutting and Laminating Techniques

The use of an ultrasonic cutter for the tread, combined with heated incisions for material head and tail, ensures clean and precise cuts. This not only enhances the appearance of the finished tire but also contributes to its overall structural integrity. The servo fixed length method employed for each layer of material ensures consistent laminating accuracy, further bolstering the quality of the final product.

High Degree of Automation and Low Labor Intensity

The Automatic Bias One Stage Tire Building Machine is designed to minimize manual intervention. Features such as the movable inner support wire placement seat, automatic drum loading of steel wire rings, and automatic tire unloading significantly reduce the labor required in the production process. The machine also allows for the management of multiple matching methods, with one-click switching of specifications, making it highly adaptable to different tire designs and production requirements.

Enhanced Safety Measures

Safety is a critical consideration in any manufacturing environment, and this machine does not disappoint. It is equipped with an active safety rope and various photoelectric switch configurations to prevent accidents. The anti-scalding and anti-pinch design, along with the safety light curtain on the operation side, further enhances the safety of workers. Additionally, the machine features a fault alarm prompt that alerts operators to any issues, allowing for prompt resolution and minimizing downtime.

Wide Range of Applications

The versatility of the Automatic Bias One Stage Tire Building Machine is another key advantage. It is suitable for the manufacture of a wide range of industrial tires, including those for motorcycles, agricultural machinery, and specialized industrial equipment. This makes it an ideal choice for manufacturers looking to diversify their product offerings without the need for multiple machines.

Equipment Parameters and Accuracy

The machine's specifications are tailored to meet the demands of industrial tire production. It can handle a wide range of material widths and thicknesses, from 80-320mm for lining to 215-340mm for treads, with material thicknesses ranging from 0.4-1.4mm to 5-14mm. The drum diameter and width ranges are also designed to accommodate various tire sizes, ensuring flexibility in production.

In terms of accuracy, the machine delivers exceptional performance. The host rail levelness is maintained within ±0.06mm/1000mm, while the carcass and tread drum main shaft runouts are kept to a minimum. The carrying ring and drum coaxiality, repeat positioning accuracy, and fixed length accuracy for each layer of material are all tightly controlled, ensuring the production of high-quality tires.

Impact on the Industrial Tire Manufacturing Industry

The adoption of automatic tire building machines like the one offered by Soniwell Group is transforming the industrial tire manufacturing landscape. By automating key processes, manufacturers can achieve higher production volumes, improved quality, and reduced costs. The enhanced safety features also contribute to a more secure working environment, protecting workers from potential hazards.

Moreover, the ability to switch between different tire specifications with ease allows manufacturers to quickly adapt to changing market demands and customer requirements. This flexibility is crucial in an industry where the need for specialized tires is growing.

Conclusion

The Automatic Bias One Stage Tire Building Machine represents a significant milestone in the journey towards fully automated tire manufacturing. Its advanced features, high degree of precision, and versatility make it an invaluable tool for manufacturers of industrial tires. As the industry continues to evolve, the adoption of such machines will undoubtedly play a crucial role in shaping the future of tire production. By embracing automation, manufacturers can enhance their competitiveness, improve product quality, and ultimately drive growth in the industrial tire market.

http://www.soniwellgroup.com

SONIWELL -

AuthorPosts

- You must be logged in to reply to this topic.