- This topic is empty.

-

AuthorPosts

-

2025-07-28 at 3:39 pm #10251In the world of interior and exterior decoration, PS skirting boards have become a preferred choice due to their lightweight nature, aesthetic versatility, and ease of installation.

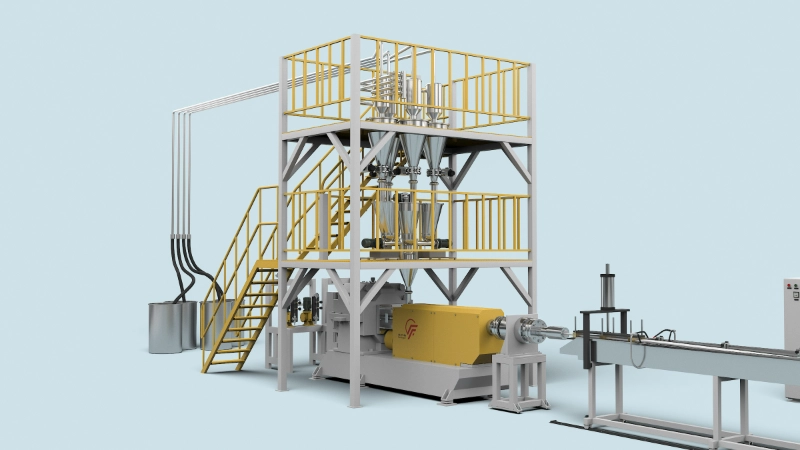

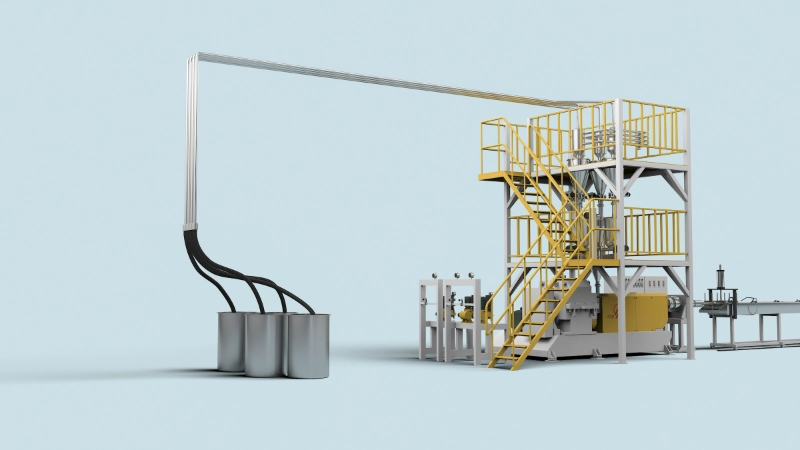

In the world of interior and exterior decoration,PS skirting boardshave become a preferred choice due to their lightweight nature, aesthetic versatility, and ease of installation. Behind these sleek decorative elements lies a sophisticated system — thePS Skirting Production Line— responsible for manufacturing high-quality products like photo frames, skirting boards, wall panels, and ceiling corners.

However, running a PS Skirting Production Line is not without challenges. Operators often make avoidable errors that compromise product quality, efficiency, and safety. In this blog, we explore the mostcommon mistakes to avoid when operating a PS Skirting Production Line, especially in setups likeFeininger’s advanced production linethat featuressupercritical CO₂ physical foamingfor superior environmental performance.

What Is a PS Skirting Production Line?

APS Skirting Production Lineis a specialized extrusion system used to manufacture polystyrene-based decorative components such as:

-

Floor skirting boards

-

Wall panels

-

Mirror frames

-

Ceiling corners

-

Indoor and outdoor decorative mouldings

Unlike traditional plastic molding systems,Feininger's PS skirting board making machineusessupercritical CO₂ physical foaming technology, significantlyreducing product densityand improving theenvironmental friendlinessof the final product.

Common Mistakes Operators Should Avoid

1.Inaccurate Raw Material Proportioning

Mistake:Adding raw materials without precise measurement.

Impact:This leads to inconsistent density, poor foam structure, and weak final products.

Solution:Use automated feeders and mixers to maintain exact proportions. For Feininger’s system, consistency is especially critical due to the nature of CO₂ physical foaming.

2.Improper Temperature Settings

Mistake:Setting the extruder or heat exchanger temperature too high or too low.

Impact:Improper temperature control can affect the homogeneity of the material and the quality of the foam.

Solution:Follow recommended temperature profiles provided by your equipment manufacturer. Feininger machines have detailed specifications for optimized temperature zones.

3.Neglecting Die Maintenance

Mistake:Ignoring the cleanliness and alignment of the extrusion die.

Impact:Clogged or misaligned dies lead to product deformities and inconsistent extrusion widths.

Solution:Regularly clean and inspect dies to maintain smooth extrusion flow. A scheduled maintenance routine ensures consistent output and longer equipment life.

4.Incorrect Foaming Agent Dosage

Mistake:Overusing or underusing the CO₂ foaming agent.

Impact:Incorrect CO₂ levels will cause uneven foaming, poor surface finish, and even structural collapse of the profile.

Solution:Ensurequantitative CO₂ injectionis accurately set and calibrated in your Feininger production line. Supercritical CO₂ requires precision for optimal cell structure.

5.Skipping Cooling and Shaping Processes

Mistake:Rushing the shaping and water cooling stages.

Impact:Products that are not adequately cooled and shaped will warp or fail quality control.

Solution:Use atwo-stage shaping jacketand water channel as designed in Feininger’s system to allow gradual and controlled solidification.

6.Poor Synchronization of Downstream Equipment

Mistake:Mismatch between extrusion speed and tractor/cutter speeds.

Impact:This leads to stretching, tearing, or inconsistent product lengths.

Solution:Synchronize all equipment stages — extruder, tractor, and cutter — via a unified control system. Feininger machines are equipped forautomated coordinationacross stages.

7.Lack of Quality Inspection

Mistake:Skipping real-time quality checks during operation.

Impact:Undetected defects can lead to entire batches of wasted production.

Solution:Implement regular inspection points for size, appearance, and density throughout the line. Invest in inline sensors if possible.

Advantages of PS Skirting Boards in Practical Applications

PS skirting boards offer a modern, lightweight, and cost-effective alternative to traditional wood or MDF trims. They aremoisture-resistant, termite-proof, and easy to clean, making them ideal for kitchens, bathrooms, and humid environments. Withprecise molding and customizable finishes, PS skirting enhances the aesthetic appeal of interiors while protecting walls from scuffs and damage. Its easy installation and long-lasting performance make it a preferred choice for residential renovations, commercial interiors, and prefab housing projects.

Why Feininger's PS Skirting Production Line Stands Out

Feininger's PS skirting line machines integratesupercritical CO₂ physical foamingrather than traditional chemical foaming. The benefits include:

-

Lower product densitywithout compromising strength

-

Environmentally friendly process(no toxic chemicals)

-

More uniform foam structurefor better surface aesthetics

-

Energy-efficient extrusion technology

Whether you’re producing mirror frames or ceiling mouldings, Feininger offersstable, efficient, and sustainable solutionsfor manufacturers looking to elevate quality and reduce carbon footprint.

Final Tips for Optimizing Your PS Skirting Production Line

-

Train your operatorsthoroughly on equipment handling and maintenance

-

Document operating proceduresand settings for each product type

-

Run small test batchesafter any equipment adjustment

-

Work with a trusted manufacturerlike Feininger to ensure long-term support and customization

Frequently Asked Questions (FAQs)

Q1: How is physical foaming better than chemical foaming in PS skirting production?

A1:Physical foaming with supercritical CO₂ produces lower-density products without using harmful chemicals, resulting in cleaner and more consistent foam structures.Q2: What kind of products can be made on a PS Skirting Production Line?

A2:Products include skirting boards, wall panels, photo frames, ceiling corners, decorative mouldings, and more.Q3: Can Feininger's PS skirting line be customized?

A3:Yes, Feininger offers flexible customization based on product design, size, foaming ratio, and production capacity.Conclusion

Operating aPS Skirting Production Linerequires technical knowledge, attention to detail, and a commitment to precision. By avoiding the common mistakes outlined above and choosing a cutting-edge solution like Feininger's CO₂-based system, manufacturers can achievehigher product quality,environmental compliance, andgreater operational efficiency.

For businesses looking to upgrade or invest in a new PS skirting system,Feininger's advanced production linesprovide the technology and support needed to stay ahead in a competitive market.

http://www.china-feininger.com

Feininger (Nanjing) Energy Saving Technology Co.,ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.