- This topic is empty.

-

AuthorPosts

-

2025-09-05 at 11:44 am #10555

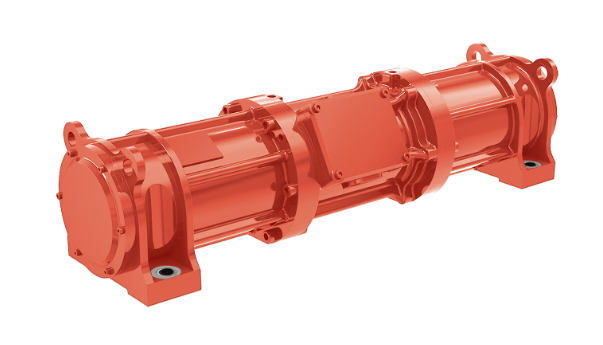

In industries such as mining, chemical processing, petroleum, and metallurgy, equipment safety and performance are crucial. One of the most reliable solutions for powering vibrating machines in hazardous environments is the SUDA MOTOR's three-stage long explosion-proof vibration motor. Designed with advanced technology and robust construction, this motor ensures stable operation, high efficiency, and long service life while meeting stringent explosion-proof standards.

What is a Three-Stage Long Explosion-Proof Vibration Motor?

A three-stage long explosion-proof vibration motor is a specialized type of industrial motor engineered to deliver consistent vibration force for material handling and processing equipment. Unlike conventional motors, this model features:

Three-stage design – ensuring smooth operation, strong vibration output, and precise performance adjustment.

Explosion-proof structure – preventing sparks or heat accumulation, making it safe to operate in flammable and combustible environments.

Long-body construction – providing higher torque and increased vibration amplitude for demanding applications.

These design features make the motor suitable for industries where both safety and efficiency are non-negotiable.

Key Features of the Motor

Explosion-Proof Safety

Built to comply with international explosion-proof standards, this motor ensures reliable performance in environments with dust, gas, or chemical risks.

High Durability

The housing is manufactured from robust cast iron or alloy steel, ensuring excellent resistance to impact, wear, and corrosion.

Stable Vibration Performance

Equipped with precisely designed eccentric blocks, the motor provides stable and adjustable vibration force to meet diverse processing requirements.

Extended Service Life

With optimized bearings, efficient cooling systems, and strong sealing protection, the motor is capable of continuous operation under heavy loads.

Energy Efficiency

Advanced winding and insulation technology reduces energy consumption, ensuring cost-effective long-term use.

Applications of Three-Stage Long Explosion-Proof Vibration Motor

This motor is widely used in hazardous environments where vibration is essential for material transport, screening, or compaction. Typical applications include:

-

Mining industry: driving vibrating screens, feeders, and crushers for ore processing.

-

Chemical plants: operating vibratory conveyors and mixers in flammable production areas.

-

Petroleum industry: assisting with vibration equipment for drilling mud separation and material filtration.

-

Metallurgy: powering vibrating casting tables and material handling machines.

-

Construction: used in vibrating compactors and sieving systems for aggregates and cement.

Its versatility and safety make it a critical component in industries that demand both efficiency and explosion protection.

Advantages Over Conventional Motors

-

Enhanced Safety: Unlike standard motors, explosion-proof models minimize the risk of ignition in volatile environments.

-

Stronger Output: The three-stage design allows for higher amplitude and precise vibration control.

-

Low Maintenance: Built with heavy-duty components that reduce downtime and servicing costs.

-

Long-Term Reliability: Designed to withstand harsh working conditions without compromising performance.

-

Customizability: Available in various vibration frequencies, force ranges, and installation configurations to meet different operational needs.

Choosing the Right Explosion-Proof Vibration Motor

When selecting a three-stage long explosion-proof vibration motor, companies should consider:

-

Required vibration force – depends on the material type and processing method.

-

Explosion-proof grade – ensuring compliance with safety regulations of the operating environment.

-

Installation design – horizontal or vertical mounting based on machine structure.

-

Load capacity and duty cycle – ensuring the motor matches the workload demands.

Partnering with a trusted manufacturer ensures proper customization, long-term technical support, and compliance with safety certifications.

Conclusion

The durable three-stage long explosion-proof vibration motor is a powerful and safe solution for hazardous environments where performance and reliability are essential. With its explosion-proof design, long-body structure, and stable vibration output, it is widely adopted in industries such as mining, chemical, petroleum, and metallurgy.

By combining advanced technology with superior durability, this motor not only improves operational efficiency but also ensures worker safety and long-term stability. Investing in this type of motor is a strategic decision for companies aiming to enhance productivity while complying with strict safety standards.

https://www.sudazhendong.com/durable-three-stage-long-explosion-proof-vibration-motor.html

http://www.sudazhendong.com

https://www.sudazhendong.com/about-us.html -

-

AuthorPosts

- You must be logged in to reply to this topic.