- This topic is empty.

-

AuthorPosts

-

2025-09-09 at 4:01 pm #10598

In the modern world of industrial processing, manufacturers face ever-increasing demands for efficiency, precision, and adaptability. Whether blending high-viscosity pastes, stabilizing emulsions, or uniformly suspending solids in liquids, the choice of mixing technology can determine not only product quality but also process economy.

Among the many mixing solutions available, multi-shaft mixers stand out for their versatility, scalability, and precision control. These systems can handle a wide variety of mixing challenges, from delicate emulsification to high-load dispersion — all within a single vessel.

At Orisun, a company specialized in mechanical design and manufacturing, we develop tailored mixing equipment that reflects decades of engineering experience. Our multi-shaft mixers are purpose-built for demanding industries such as pharmaceuticals, cosmetics, chemicals, and food processing.

In this article, we explore how multi-shaft mixers provide versatile solutions for both emulsions and suspensions, and how Orisun’s engineering approach ensures high-performance, application-specific results.

What Is a Multi-Shaft Mixer?

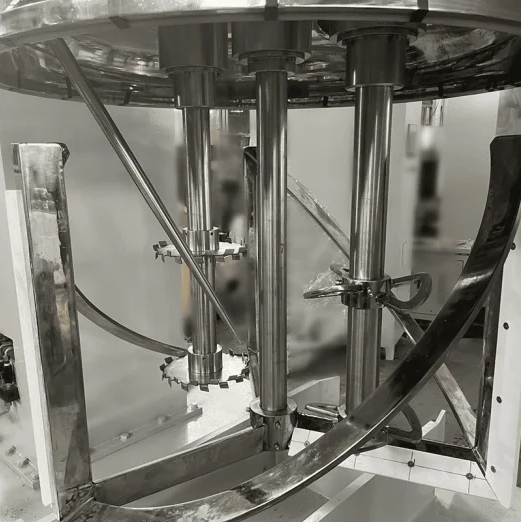

A multi-shaft mixer combines two or more independently driven agitators within a single vessel. Typical configurations include:

High-speed disperser: For breaking down solids, powders, or agglomerates

Low-speed anchor or paddle: For bulk flow, scraping, and heat distribution

High-shear rotor-stator (optional): For intense emulsification or homogenization

This flexible design enables simultaneous macro and micro mixing, making it ideal for multi-phase formulations such as:

Oil-in-water or water-in-oil emulsions

Creams, gels, and lotions

Pigmented suspensions

Heat-sensitive materials

Polymers and adhesives

1. Emulsions: Achieving Stable Phase Distribution

Emulsions are mixtures of two immiscible liquids, where one phase is dispersed into another (e.g., oil in water). Creating a stable emulsion requires:

High shear to reduce droplet size

Uniform energy distribution

Precise control of temperature and mixing time

Multi-shaft mixers solve these challenges by combining a high-speed disperser or rotor-stator head with a low-speed sweeping agitator. While the high-shear unit breaks droplets down into fine sizes, the anchor gently moves the batch to prevent overheating or dead zones.

At Orisun, we design emulsifying systems with custom shear geometries and programmable mixing cycles to meet the specific rheology and stability demands of the formulation.

2. Suspensions: Preventing Settling and Ensuring Homogeneity

Suspensions involve solid particles dispersed in a liquid. Without adequate mixing, particles tend to settle or float, leading to inconsistent product quality.

Multi-shaft mixers provide:

Uniform suspension via robust bulk flow

Controlled turbulence to keep particles moving

Scraping action to prevent material buildup on vessel walls

This makes them ideal for paints, ceramic slurries, mineral dispersions, and pharmaceutical suspensions.

Orisun’s low-speed agitators are equipped with Teflon or metal scrapers, precision-welded to follow vessel contours for complete mixing and easy cleaning — a critical advantage in GMP environments.

3. High Viscosity Blending: Power Meets Precision

In applications such as adhesives, sealants, and polymer gels, viscosity can exceed hundreds of thousands of centipoise. High-viscosity blending demands equipment that can handle torque-intensive operations while still delivering uniformity.

Multi-shaft mixers shine here due to:

Independent drive motors for torque customization

Efficient material turnover, even at high viscosities

Capability for vacuum operation or jacketed heating/cooling

Orisun engineers high-torque multi-shaft mixers with reinforced shafts, gearbox optimization, and thermal control integration for flawless mixing of dense, sticky, or shear-sensitive materials.

4. Heating, Cooling & Vacuum Integration

Many processes require thermal management or operation under vacuum to eliminate air bubbles or moisture. Multi-shaft mixers accommodate:

Jacketed vessels for temperature control

Vacuum sealing systems to reduce oxidation and entrapped air

CIP/SIP systems for hygienic applications

Orisun manufactures mixing vessels with precision-machined jackets and vacuum-rated seals, offering complete turnkey systems for regulated industries.

5. One Mixer, Multiple Functions: Streamlining Process Steps

Because of their modular design, multi-shaft mixers can perform multiple operations in one batch cycle, such as:

Wetting and dispersing powders

Emulsifying and stabilizing

Heating/cooling

Vacuum degassing

Final polishing or de-aeration

This reduces the need for transfers, minimizes contamination risks, and significantly increases throughput.

Orisun’s integrated control systems offer programmable mixing stages, batch recording, and real-time feedback — making automation seamless and production traceable.

Applications Across Industries

Pharmaceuticals: Ointments, suspensions, topical creams

Cosmetics: Emulsions, lotions, mascaras

Food & Beverage: Sauces, syrups, dairy blends

Chemicals: Lubricants, resins, inks

Adhesives & Sealants: Two-component systems, pastes, elastomers

Why Choose Orisun for Multi-Shaft Mixing Solutions?

As a company rooted in precision mechanical design and manufacturing, Orisun provides:

Custom-built mixing systems for your formulation and process needs

In-house engineering support from concept to commissioning

Robust stainless-steel fabrication meeting industrial and hygienic standards

Full control system integration including PLCs, HMIs, and data tracking

Post-installation service and technical training

We don’t just manufacture mixers — we engineer process solutions.

Conclusion

From stabilizing fine emulsions to ensuring consistent suspensions, multi-shaft mixers are indispensable tools for modern process industries. Their versatility, efficiency, and precision make them a smart investment for manufacturers seeking to optimize product quality and operational control.

At Orisun, we bring decades of mechanical design expertise to deliver mixing systems tailored to your exact needs — helping you scale production, reduce variability, and unlock better process outcomes.

Looking for a customized multi-shaft mixer solution?

Contact Orisun today to discuss your process requirements and explore how our technology can transform your production line.

Visit our website http://www.orisunmachinery.com to learn more about our mixer series, technical specs, and engineering capabilities.

The Ultimate Guide to Multi-Shaft Mixers: Functions, Types, and Advantages

-

AuthorPosts

- You must be logged in to reply to this topic.