- This topic is empty.

-

AuthorPosts

-

2025-07-25 at 4:50 pm #10209

In today’s competitive manufacturing landscape, improving product quality is essential for staying ahead. One critical area where manufacturers can gain an edge is through professional hood processing services. A precisely processed hood not only enhances the overall product performance but also boosts durability and customer satisfaction. Hangzhou Hengli Metal Processing Co., Ltd., a modern enterprise specializing in metal supply chain integration, excels in providing tailored hood processing services that meet stringent quality standards across multiple industries including automotive, energy, and heavy machinery. This article explores practical ways to improve product quality by leveraging Hengli’s professional hood processing services.

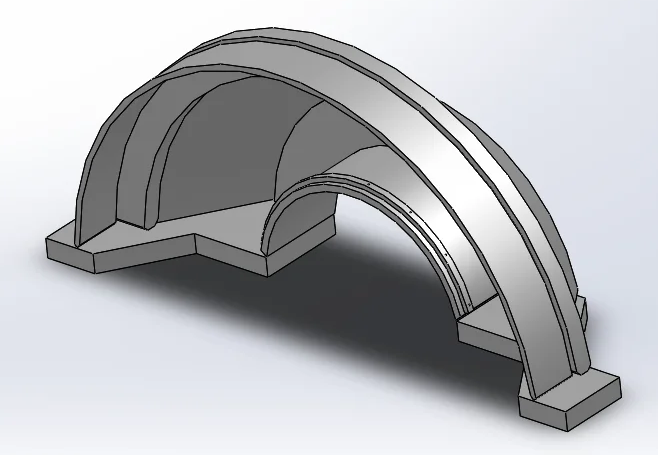

1. Understanding Hood Processing Services and Their Impact on Quality

Hood processing services involve various manufacturing steps such as profile cutting, forming, welding fabrication, and machining of heavy plates. These processes transform raw metal sheets into precisely crafted hoods that fit perfectly and perform reliably. Hengli’s capability to flame cut plates up to 500mm thick, combined with their ASME IX and TUV (EN278) welding certifications, ensures welding quality that meets international standards. When every stage of hood processing is executed with precision and care, the resulting products have superior structural integrity and surface finish, key factors in product quality.

2. Utilize Advanced Cutting Technologies for Accuracy

Accurate cutting is the foundation of high-quality hood manufacturing. Hengli employs advanced technologies such as laser cutting, CNC machining, and waterjet cutting to achieve precise dimensions and clean edges. Laser cutting, in particular, provides fine detail and minimal heat distortion, essential for maintaining tight tolerances and reducing post-processing work. By choosing a professional service that uses such cutting-edge technology, manufacturers can minimize errors, ensure consistency across batches, and reduce waste — all directly contributing to improved product quality.

3. Custom Tailored Solutions for Unique Customer Requirements

Every customer’s hood processing needs are different, depending on their design, industry standards, and application. Hengli recognizes this diversity and offers customized solutions ranging from simple hood cutouts to complex hood assemblies. Their team collaborates closely with clients, adapting processing techniques to meet specific requirements. This level of customization prevents common issues like poor fit or premature wear, enhancing the product’s longevity and performance. Tailored hood processing is a powerful way to improve quality because it aligns manufacturing exactly with design intent and functional demands.

4. High-Quality Welding Ensures Structural Strength and Durability

Welding quality is a crucial factor in hood manufacturing since it affects structural strength and durability. Hengli’s ASME IX and TUV (EN278) certified welders use the latest welding fabrication techniques to join heavy plates with high precision and strength. Proper welding prevents cracks, deformations, and weak points that could lead to product failure. Furthermore, consistent welding quality allows manufacturers to confidently deliver products that withstand harsh operating environments, significantly elevating overall product quality.

5. Finishing Processes Enhance Appearance and Protection

Beyond shaping and welding, finishing processes are vital to the final product quality. Hengli offers a range of finishing services such as painting, powder coating, and anodizing to meet aesthetic and protective requirements. These finishes not only improve the hood’s appearance but also provide corrosion resistance and durability, which are critical for products exposed to tough conditions. Well-executed finishing extends the service life of the hood and preserves its functional integrity, adding value to the end product.

6. Comprehensive Hood Services Support Quality Throughout the Lifecycle

Improving product quality isn’t just about manufacturing. Hengli also provides complementary hood services including design consultation, testing, and repair. Through design assistance, clients can optimize hood structures for manufacturability and performance. Rigorous testing ensures that hoods meet all quality and safety standards before delivery. Additionally, professional repair services extend product life and maintain quality after deployment. These comprehensive services help customers maintain high standards from design to end-of-life, reinforcing the importance of professional hood processing beyond initial fabrication.

7. Why Partner with Hangzhou Hengli Metal Processing Co., Ltd.?

Choosing the right partner is critical for improving product quality through hood processing. Hengli stands out due to its integration of advanced technology, skilled workforce, and deep industry experience. The company serves diverse fields such as automotive, aerospace, construction machinery, agriculture, special vehicles, and energy sectors. Hengli’s customer-centric approach ensures customized, high-quality solutions delivered on time and within budget. Their commitment to quality is reflected in international welding certifications and a reputation for reliability. By partnering with Hengli, manufacturers can confidently improve their product quality, reduce defects, and enhance customer satisfaction.

Conclusion: Enhancing Product Quality with Professional Hood Processing Services

In conclusion, professional hood processing services play a pivotal role in elevating product quality. Leveraging advanced cutting and welding technologies, customized solutions, and comprehensive support, companies like Hangzhou Hengli Metal Processing Co., Ltd. help manufacturers deliver hoods that meet the highest standards of precision, durability, and finish. Whether you operate in automotive, energy, or heavy machinery industries, Hengli’s expertise ensures your hood components are made to exacting specifications, improving your overall product quality and market competitiveness. Investing in professional hood processing is not just about manufacturing; it’s about building lasting value into every product.

http://www.hlmetal.net

HENGLI -

AuthorPosts

- You must be logged in to reply to this topic.