- This topic is empty.

-

AuthorPosts

-

2025-06-11 at 6:06 pm #9789

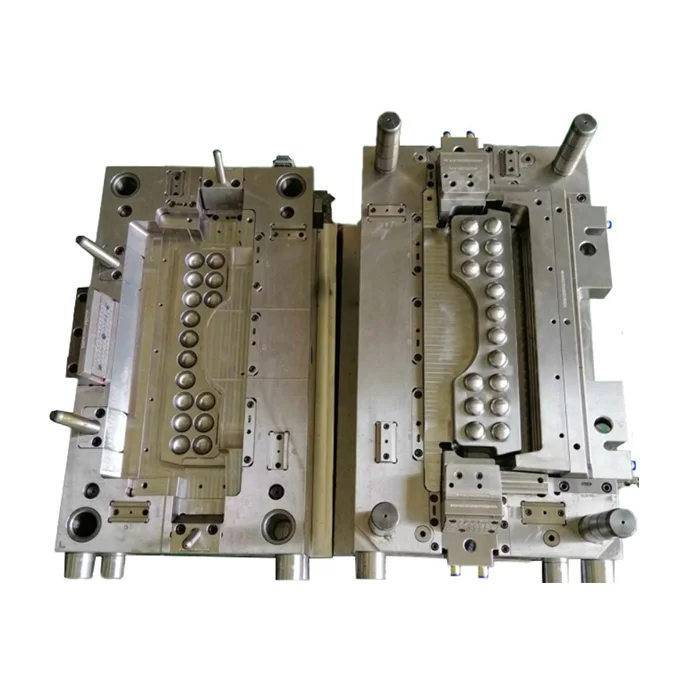

The demand for high-performance plastic components across industries such as automotive, medical and electronics necessitates the production of high precision plastic injection molds. These molds must meet tight dimensional tolerances, maintain structural integrity over long production cycles, and deliver consistent part quality. Achieving such standards requires a meticulously controlled manufacturing process, which integrates advanced machining technologies, skilled craftsmanship, and rigorous quality control. In this blog post, as a professional custom precision injection mold manufacturer, Xuzhong will share the manufacturing process of high precision plastic injection mold for sale.

High Precision Plastic Injection Mold Manufacturing Process

1. Design and Engineering Analysis

The first and arguably most critical phase in the manufacturing of a high precision mold is the design stage. Here, CAD (Computer-Aided Design) software is used to model both the product and the mold components. The mold design must consider part geometry, expected shrinkage, gating system, cooling channels, venting, and ejection mechanisms.

Key Steps:

* Part Design Validation: The plastic part design is assessed for manufacturability. DFM (Design for Manufacturability) principles are applied to ensure that the part can be reliably molded.

* Mold Flow Analysis: Using software like Moldflow or Sigmasoft, simulation is conducted to analyze plastic flow, identify potential defects such as air traps or weld lines, and optimize the gate location and cooling layout.

* Tolerance Analysis: High precision molds often demand tolerances as tight as ±0.01 mm. These tolerances are factored into every aspect of the mold design.

Once the design is finalized, detailed 2D drawings and 3D models of each mold component are generated to guide the machining and assembly processes.

2. Material Selection and Procurement

High precision molds are typically made from premium-grade tool steels that offer wear resistance, dimensional stability, and machinability. Commonly used materials include:

* P20 Tool Steel: Pre-hardened steel ideal for moderate production runs.

* H13: A chromium hot-work steel with high toughness and thermal fatigue resistance.

* Stainless Steels (e.g., 420, S136): Suitable for corrosion-resistant applications, especially in the medical or food sectors.

* Beryllium-Copper Alloys: Used selectively for inserts or cores requiring superior thermal conductivity.

All material batches undergo hardness testing, ultrasonic inspection, and certification validation before proceeding to machining.

3. Rough Machining

The selected materials are initially cut to rough dimensions using band saws and then pre-machined using CNC milling and turning centers.

Key Processes:

* Rough CNC Milling: Achieves general shape and removes excess material.

* Drilling for Cooling Channels and Fasteners: Precise holes are made for future assembly and cooling integration.

* Stress Relieving: After rough machining, the mold base and core blocks are heat-treated to relieve internal stresses, preventing deformation during finishing.

This stage prioritizes maintaining allowance for final precision machining while ensuring flatness and squareness of all surfaces.

4. Heat Treatment

Heat treatment is crucial for enhancing the mechanical properties of mold components, particularly for high wear and stress areas like cavities, cores, and slides.

Common Treatments:

* Hardening and Tempering: Tool steels like H13 are hardened to 48–52 HRC and then tempered to balance hardness and toughness.

* Vacuum Heat Treatment: Minimizes oxidation and dimensional distortion.

* Cryogenic Treatment: Sometimes used to stabilize steel structures at sub-zero temperatures for improved wear resistance.

Post-treatment, the components are re-verified for dimensional stability before final machining.

5. Precision Machining

Precision machining is where the mold truly begins to take shape. CNC equipment with multi-axis capabilities and micron-level accuracy is used to achieve the required dimensional tolerances and surface finishes.

Key Technologies:

* High-Speed CNC Milling: Enables tight tolerance machining of complex 3D geometries. Advanced 5-axis machines ensure smooth surface contours.

* EDM (Electrical Discharge Machining): Ideal for sharp corners and intricate features that cannot be machined by conventional milling. This includes both sinker EDM and wire EDM.

* Grinding: Surface grinders and jig grinders are used to finish flat surfaces, slides, and fitting elements to sub-micron accuracy.

* Coordinate Measuring Machines (CMM): Used to verify tolerances and ensure each component matches the digital model precisely.

Depending on part complexity, multiple iterations of machining and inspection may be performed.

6. Polishing and Surface Finishing

High precision molds often require surface finishing to meet optical or cosmetic requirements. In industries like consumer electronics or automotive interiors, surface aesthetics are critical.

Finishing Techniques:

* Manual Polishing: Skilled technicians use diamond paste, sandpaper, and buffing wheels to achieve mirror finishes (Ra < 0.05 µm) on cavity surfaces.

* Texturing or Etching: Chemical or laser etching techniques are applied to replicate leather, matte, or custom textures.

* Coatings: PVD (Physical Vapor Deposition) or nitriding may be applied to enhance surface hardness and reduce friction.

This stage directly influences the appearance of the final molded part and its release characteristics.

7. Mold Assembly

After all components have passed quality inspections, they are assembled into the final mold tool.

Assembly Considerations:

* Component Fitment: Tight tolerances are verified to ensure that cores, cavities, sliders, and lifters fit precisely and operate smoothly.

* Cooling System Integration: All cooling lines, baffles, and bubblers are assembled and leak-tested under pressure.

* Ejection System Installation: Ejector pins, sleeves, and hydraulic or mechanical actuation systems are mounted with proper alignment.

* Hot Runner Installation (if applicable): For molds using hot runners, manifolds and nozzles are installed and electrically tested.

Lubrication and initial cycle testing of moving elements ensure the mold is ready for tryouts.

8. Trial Molding and Optimization

Before the mold is shipped or approved for mass production, several mold trials are conducted to validate its performance.

Evaluation Parameters:

* Dimensional Accuracy of Parts: Measured using CMMs or optical comparators.

* Cycle Time: Optimized by adjusting cooling efficiency and injection parameters.

* Defect Analysis: Short shots, flash, warpage, sink marks, and weld lines are identified and eliminated via design or process changes.

Adjustments may involve fine-tuning injection speeds, gate designs, or cooling circuits. Sometimes, minor modifications to the mold geometry are made to perfect the output.

9. Final Validation and Documentation

Once the mold produces acceptable parts consistently and meets all performance metrics, it undergoes final validation.

Documentation Includes:

* Inspection Reports

* Material Certifications

* Mold Maintenance Guide

* 2D and 3D CAD Files

* Trial Shot Samples

A final FAT (Factory Acceptance Test) is typically conducted in the presence of the customer or their quality representatives.

10. Shipping and Post-Sale Support

The validated mold is prepared for shipping, often involving anti-corrosion treatment, protective packaging, and documentation. For offshore molds, compliance with international standards and shipping protocols is essential.

After delivery, many mold makers offer on-site support for mold installation, start-up, and training.

Conclusion

The manufacturing of high precision plastic injection molds is a multidisciplinary endeavor combining engineering excellence, cutting-edge technology, and uncompromising quality assurance. From concept to commissioning, every stage requires accuracy, expertise, and attention to detail. As product designs grow increasingly complex and tolerance requirements tighten, the role of precision mold manufacturing becomes ever more critical to the success of modern plastic production.

http://www.xuzhongmold.com

Xuzhong -

AuthorPosts

- You must be logged in to reply to this topic.