- This topic is empty.

-

AuthorPosts

-

2025-12-10 at 4:05 pm #11466

As the dental industry continues to evolve toward digital and intelligent manufacturing, precision and consistency have become essential standards in clear aligner production. Every aligner must fit perfectly, ensuring comfort, accuracy, and safety. Yet, one critical step—the trimming process—has traditionally been dependent on manual operations, making it prone to inconsistency and inefficiency.

To meet these challenges, ConverSight introduces its next-generation Automatic Trimming Machine ACTA-B, a breakthrough in orthodontic automation that delivers unmatched precision and full workflow integration. Designed for trimming thermoformed dental model blanks into their final shape, this system combines robotic control, intelligent software, and real-time recognition for an optimized aligner finishing experience.

The Need for Automation in Trimming

In a conventional aligner production setup, trimming often remains the most labor-intensive stage. Skilled operators manually cut aligners around dental models using handheld or semi-automatic tools. This process can result in:

Irregular edges due to operator fatigue or inconsistent cuttiang angles.

High rework rates from uneven trimming or material residue.

Low throughput, as manual trimming limits production speed.

Greater labor dependency, making scalability difficult.

As global demand for invisible aligners grows, these issues have become bottlenecks for dental labs and manufacturers seeking efficiency and quality consistency.

ConverSight Automatic Trimming Machine addresses these problems directly—transforming trimming into a precise, automated, and intelligent process.

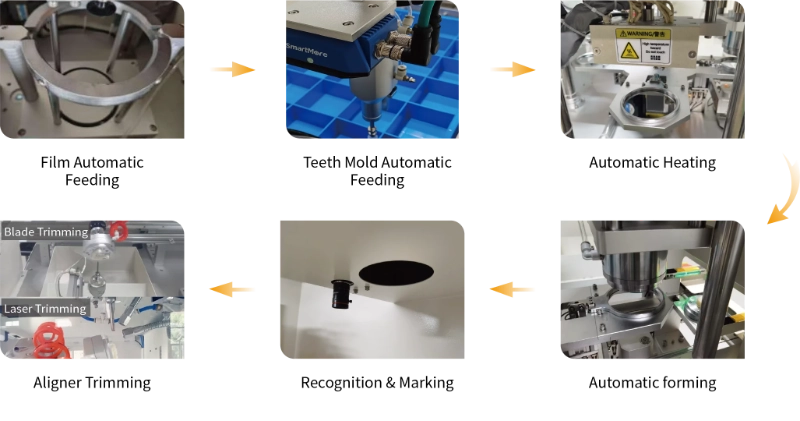

Workflow Overview

The Automatic Trimming Machine ACTA-B is integrated seamlessly into the full aligner production line, completing the final stage of the workflow.

1. Film Automatic Cutting

The system automatically cuts thermoforming film materials to the required size, ensuring minimal waste and smooth transitions between forming and cutting.2. Automatic Teeth Mold Feeding

Dental models are automatically loaded and positioned with visual recognition technology. Up to 10 trays of teeth molds can run continuously for an hour without manual supervision, enabling uninterrupted production.3. High-Pressure Thermoforming

Film sheets are evenly heated and softened, with adjustable temperature control (ranging up to 700°C) and high precision temperature sensors. This ensures optimal fit for the clear aligner prototype.4. Robotic Trimming and Finishing

Here, the ACTA-B takes center stage. A high-precision ABB six-axis robotic arm controls the trimming tool, executing millimeter-level synchronous movements. The built-in software calculates the exact trim line for each aligner, removing residue material and refining edges to perfection.

The finished aligner comes out with a clean, uniform and smooth edge—ready for inspection, polishing,cleaning,packaging, and delivery.

Technical Features that Set It Apart

Full Workflow Automation

The ACTA-B enables a closed-loop process from film roll to finished aligners. Each stage communicates digitally, reducing manual intervention and eliminating cross-process errors.

Smart Cutting System

Equipped with an automatic film cutting module, the system ensures consistent material preparation. This not only saves time but also improves yield by minimizing leftover waste,reducing material cost.

Intelligent Teeth Mold Recognition

The integrated vision system identifies each dental model’s position, orientation, before loaded on the machine fixture. This ensures that every aligner aligns precisely with its corresponding mold.

Adaptive Thermoforming Compatibility

The trimming system works in harmony with ConverSight thermoforming equipment, capable of handling aligners formed under high pressure with varying thickness,in different brands of the film.

Millimeter-Level Robotic Precision

The ABB six-axis robot ensures cutting accuracy within millimeter tolerances. Its synchronized motion control allows flexible trimming of complex, curved, or irregular aligners, a task nearly impossible to standardize manually.

Enhanced Edge Refinement

The trimming head—designed for both blade and laser finishing—refines the aligner edges, eliminating burrs or roughness that could cause discomfort during wear.

The Advantage: Quality and Efficiency in Harmony

By integrating the Automatic Trimming Machine ACTA-B, manufacturers experience multiple advantages that redefine their production benchmarks:

Higher Productivity – Continuous automated trimming reduces idle time between processes.

Consistent Accuracy – Each aligner is produced to exact specifications, ensuring uniformity.

Reduced Labor Costs – Few operators are required, lowering overhead without compromising output.

Better Material Utilization – Smart cutting paths and precision tools minimize film waste.

Improved Product Quality – Smooth, burr-free edges enhance patient comfort and aligner aesthetics.

Scalable Design – Easily adaptable to production lines of various capacities.

The combination of robotic control, intelligent sensing, and adaptive software transforms trimming from a repetitive manual task into an exact science.

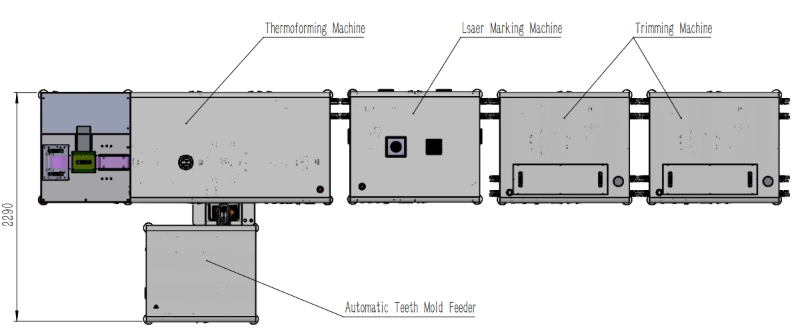

Integration into the Smart Orthodontic Production Line

The ACTA-B is more than a standalone machine—it’s part of ConverSight’s comprehensive orthodontic automation ecosystem. When paired with the Automatic Teeth Model Loading Machine, Laser Marking System, and Thermoforming Machine, it completes a digital workflow that operates autonomously from start to finish.

The machine connects seamlessly to the HyperBrain Orthodontics AI Platform, ConverSight proprietary control system that manages the entire production line. Through HyperBrain Orthodontics, operators can monitor real-time performance, receive alerts, and analyze production data to continually improve efficiency.

This integration represents the true spirit of “intelligent manufacturing”—a production system that thinks, learns, and adapts.

Real-World Impact

For dental labs and aligner manufacturers adopting the Automatic Trimming Machine ACTA-B, the benefits go beyond efficiency.

Reduced turnaround time allows faster response to customer orders.

Quality consistency strengthens brand reputation and customer trust.

Predictable cost structure improves budgeting and scalability for expanding operations.

Many users report that after upgrading to the ACTA-B, the rework rate has dropped dramatically, while throughput and product precision improved. The investment quickly pays off in both productivity and long-term sustainability.

The Future of Aligner Finishing

As the aligner industry advances, the demand for accuracy, speed, and digital traceability will continue to grow. Machines like ConverSight all in one machine ACTA-B represent the future—where robotic precision meets intelligent automation.

By eliminating the variability of manual trimming, the system ensures that each aligner delivered to patients worldwide meets the same high-quality standard, whether produced in Europe, Asia, or North America.

For manufacturers seeking to modernize their facilities, the Automatic Trimming Machine ACTA-B is not merely an equipment upgrade—it’s a strategic leap into the next generation of orthodontic aligner manufacturing.

http://www.conversighttech.com

ConverSight Technology Limited -

AuthorPosts

- You must be logged in to reply to this topic.