- This topic is empty.

-

AuthorPosts

-

2025-08-25 at 5:25 pm #10439

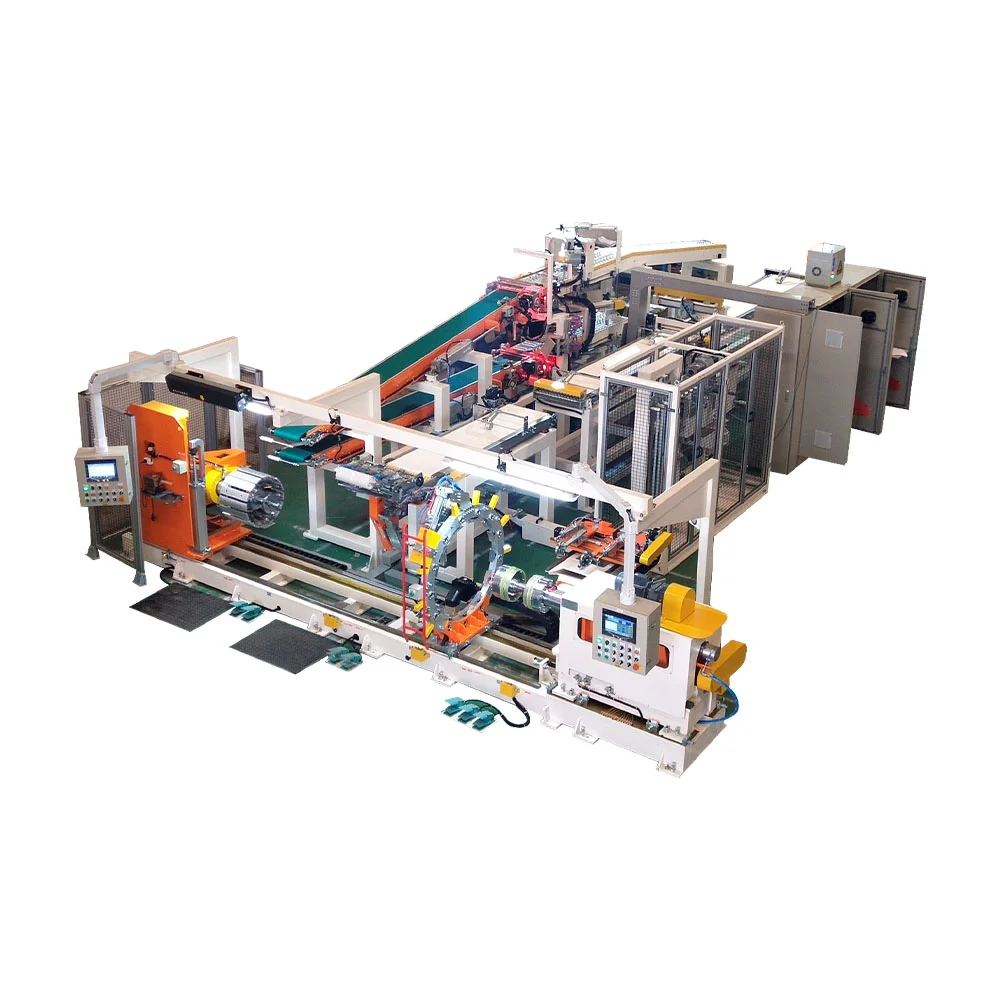

In today' s tire industry, precision and automation determine product performance and production efficiency. Among the most critical equipment in tire manufacturing is the Second-Stage Tire Building Machine, a system designed to ensure the accurate assembly of components during the tire' s shaping process. From high-performance (HP) and ultra-high-performance (UHP) tires to SUV, MT, and AT tires, this machine plays a pivotal role in meeting both performance standards and mass-production demands. In this blog post, SONIWELL, as a high quality tire building equipment seller, will share the applications of second-stage tire building machine for sale, its advantages, etc.

What is Second-Stage Tire Building Machine?

The second-stage tire building machine is a specialized piece of equipment used in the final stages of tire construction. While the first stage involves assembling basic components like the carcass and beads, the second stage focuses on combining structural elements such as belts, crown strips, and tread to shape the green tire into its final form.

This process is critical because it determines tire durability, uniformity, and performance. By integrating advanced servo-driven controls, deviation correction systems, and precise tension regulation, the machine guarantees both high productivity and consistent product quality.

Applications of Second-Stage Tire Building Machines

A second-stage HP/UHP/SUV tire building machine is suitable for a wide range of products:

-

HP (High Performance) Tires: Designed for passenger cars requiring high grip and stability.

-

UHP (Ultra-High Performance) Tires: Suited for sports cars and vehicles demanding superior speed capability.

-

SUV Tires: Built for durability and load-bearing capacity.

-

MT (Mud Terrain) & AT (All Terrain) Tires: Designed for off-road performance, where robustness and traction are crucial.

By adapting to different production requirements, the second-stage tire building machine ensures manufacturers can flexibly meet diverse market needs.

Automation in Second-Stage Tire Building

One of the key features of a second-stage tire building system is its automation capability. From belt feeding to tread cutting, automation minimizes human error, reduces waste, and increases production efficiency.

-

Automatic Deviation Correction: The belt feeding rack integrates correction technology to ensure precise positioning.

-

CCD Camera Integration: Real-time deviation detection using camera systems ensures accuracy in crown strip and belt placement.

-

Ultrasonic Tread Cutting: Enhances cutting precision and ensures smooth edges for a consistent build.

-

Automated Pre-Cutting and Joint Detection: Optional systems further refine accuracy and quality assurance.

By adopting automation, the tire plant can reduce downtime while improving the repeatability of the production process.

Control Systems in Second-Stage Tire Building

The tire building machine second stage offers flexibility in terms of control systems. Options include MITSUBISHI, SIEMENS, and AB automation platforms. These globally recognized systems provide:

-

Stable and user-friendly interfaces for operators.

-

Reliable data collection and real-time monitoring of production processes.

-

High compatibility with servo-driven components for accuracy in positioning and tension control.

The choice of control system allows manufacturers to standardize equipment with their existing automation infrastructure, ensuring seamless integration into the production line.

Servo Technology and Precision Transmission

A critical innovation in the second-stage tire building machine is the full-range servo system used for the main engine, rear pressure mechanism, and transmission mechanism. Servo control ensures:

-

High precision in movements – essential for placing belts, crown strips, and tread.

-

Stable pressure application – maintaining uniform tire structure.

-

Increased efficiency – reducing cycle times without compromising quality.

This advanced transmission design guarantees that every tire produced meets the highest molding standards.

Crown Strip Control and Tension Regulation

In the second-stage tire building process, crown strips are vital for tire strength and durability. This machine integrates a displacement sensor and proportional valve system to control tension within the range of 5–50N.

Such precise control ensures:

-

Even distribution of crown strips across the tire’s circumference.

-

Prevention of structural deformations caused by uneven tension.

-

Consistent quality for high-speed and off-road tire models.

Additionally, manufacturers can choose between belt top and bottom applications and various crown strip laying methods depending on tire design requirements.

Advanced Cutting and Heating Technology

The second-stage tire building equipment incorporates cutting-edge technologies to ensure seamless joining of materials.

-

Ultrasonic Cutting of Tread: Guarantees a clean, precise cut without material deformation.

-

Heating of Head and Tail Incisions: Ensures smooth bonding and reduces the risk of separation during tire use.

These processes improve the overall durability and safety of the finished tire.

Quality Assurance Through Smart Features

Modern second-stage tire building machines go beyond simple assembly. They integrate intelligent monitoring and correction features that support consistent production quality.

-

Joint Detection (Optional): Identifies material overlap or gaps to prevent structural weaknesses.

-

CCD Camera Feedback: Provides real-time correction for belt and crown strip deviations.

-

Process Data Logging: Ensures traceability and supports quality audits in compliance with industry standards.

With these features, manufacturers can confidently maintain uniformity across large-scale production batches.

Advantages of Using Second-Stage Tire Building Machine

While the machine offers technical sophistication, its real value lies in practical benefits for tire producers:

-

Efficiency Gains: Reduced cycle times through automation and servo technology.

-

Quality Consistency: Automated correction and tension control prevent variability.

-

Flexibility: Suitable for multiple tire types, from UHP to MT models.

-

Reduced Waste: Precise cutting and deviation correction minimize material losses.

-

Integration-Friendly: Multiple control system options adapt to existing factory infrastructure.

These advantages highlight why investment in a second-stage tire building machine is essential for modern tire manufacturers.

Future of Tire Manufacturing with Second-Stage Machines

As the demand for high-performance and specialized tires continues to rise, second-stage tire building machines will remain central to the industry’s progress. With continuous innovation in servo technology, AI-driven vision systems, and predictive maintenance, future models will offer even greater precision, speed, and sustainability.

Manufacturers that adopt advanced second-stage systems can ensure not only higher production output but also superior tire safety and performance—qualities that define competitiveness in today’s automotive market.

Conclusion

The Second-Stage Tire Building Machine represents the backbone of tire finishing operations, transforming semi-finished carcasses into high-performance products ready for the market. Through servo-driven precision, automation, advanced cutting methods, and intelligent monitoring, it guarantees both efficiency and consistency. Whether for HP, UHP, SUV, or off-road tires, this machine enables manufacturers to meet evolving demands with confidence.

By integrating advanced second-stage tire building systems into their operations, tire producers are not only improving productivity but also shaping the future of safer, stronger, and more reliable tires worldwide.

http://www.soniwellgroup.com

SONIWELL -

-

AuthorPosts

- You must be logged in to reply to this topic.