- This topic is empty.

-

AuthorPosts

-

2025-09-19 at 6:10 pm #10712

In today’s highly competitive auto body and paint repair industry, efficiency and quality are the two pillars that determine profitability. For small and medium-sized repair shops, the challenge is even greater, as they must compete with large 4S service centers while also managing costs, labor, and turnaround times.

Among all repair procedures, sanding remains one of the most labor-intensive and time-consuming tasks. Industry studies consistently show that sanding alone accounts for nearly 30% of the total time spent on surface preparation in body and paint repairs. Traditional methods, such as manual wet sanding with waterproof abrasive paper, are not only slow and physically demanding but also prone to producing inconsistent results. They create environmental issues as well, due to wastewater pollution.

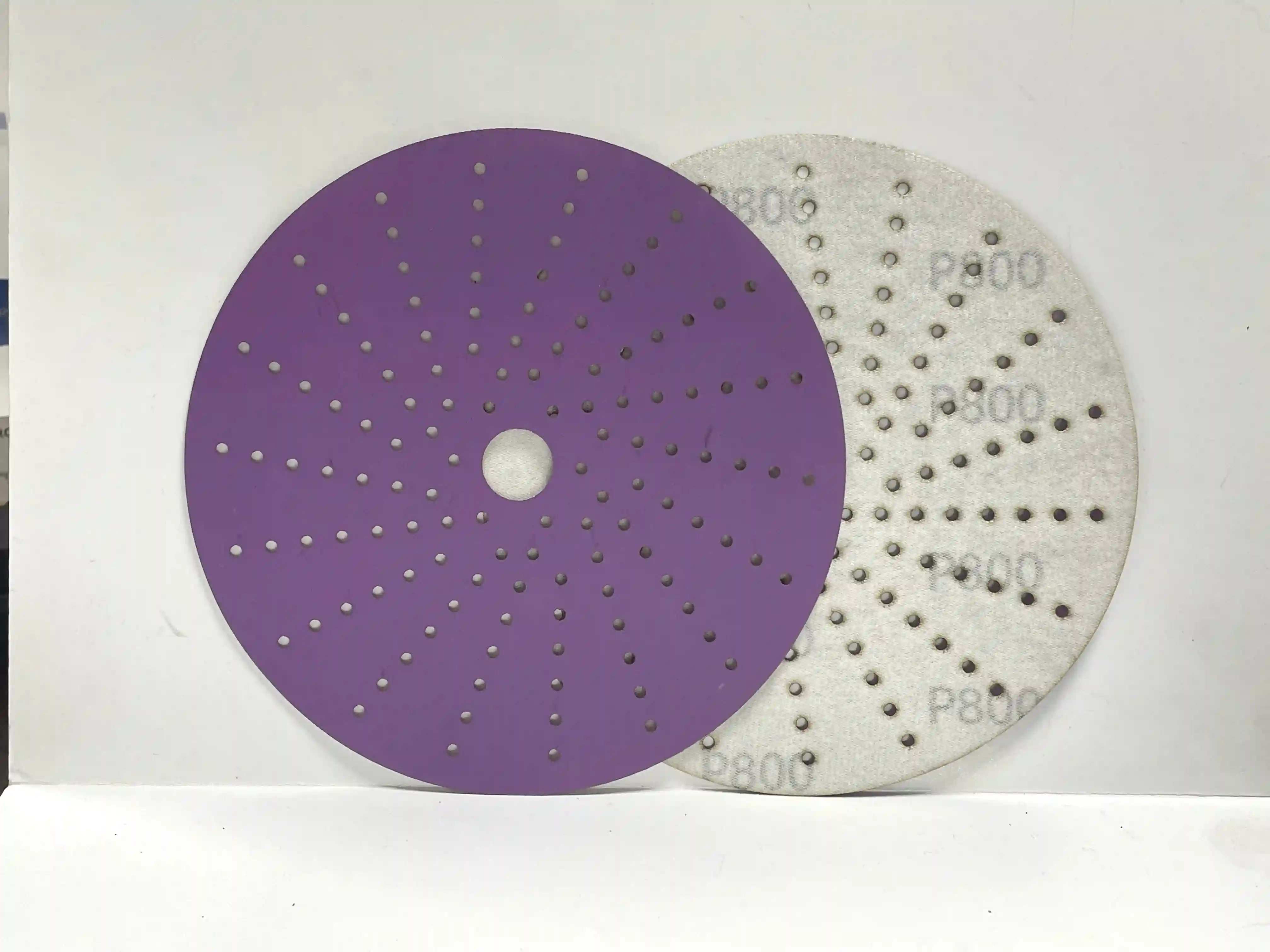

By contrast, modern dry abrasive paper technology—especially Golden Abrasives advanced purple ceramic disc—have revolutionized sanding workflows. This technology speeds up repair cycles, improves surface quality, reduces rework, and eliminates the environmental drawbacks of wet sanding. For body shops aiming to increase efficiency and profitability, upgrading to purple ceramic disc solutions is no longer an option—it is a necessity.

Why Sanding Efficiency Is Crucial in Auto Body Repair

Before diving into the unique benefits of the purple ceramic disc, it's important to understand why sanding plays such a critical role in automotive refinishing.

Time Consumption: Sanding can take up nearly one-third of the total repair time in paint restoration.

Surface Preparation: The smoothness and cleanliness of the sanded surface directly determine paint adhesion and final finish quality.

Profitability Impact: Inefficient sanding translates into higher labor costs, increased downtime, and lower throughput for repair shops.

Environmental Considerations: Wet sanding creates wastewater that requires treatment and disposal, while dry sanding eliminates this problem.

With these challenges in mind, innovative products like Golden Abrasives purple ceramic disc help shops achieve faster sanding speeds, more consistent results, and higher overall productivity.

The Power of Purple Ceramic Disc in Auto Refinishing

Golden Abrasives purple ceramic disc represents the latest generation of dry abrasive technology. Unlike traditional abrasive paper, it is engineered with advanced ceramic materials, innovative coating techniques, and precision hole patterns to optimize every aspect of the sanding process.

Let's examine the key features that make this product a standout in the automotive refinishing industry.

1. Abrasive Type: Precision-Shaped Ceramic Grains

At the core of Golden Abrasives purple ceramic disc is its precision-shaped ceramic abrasive. Traditional abrasives tend to dull quickly, leading to uneven sanding and slower cutting speeds. By contrast, ceramic abrasives are known for their hardness, durability, and sharpness.

What sets the purple ceramic disc apart is its microstructural uniformity. The grains are sharp-edged and geometrically consistent, which allows them to:

Maintain a sharper cutting edge for longer periods.

Cut faster without applying excessive pressure.

Provide cleaner, more controlled sanding results.

This means technicians can achieve high-quality finishes while reducing the number of disc changes required during a job.

2. Precision-Shaped Abrasive Technology

Golden Abrasives purple ceramic disc incorporates precision shaping technology, where each abrasive grain is aligned in an optimal orientation on the disc’s surface.

This engineered grain alignment ensures that:

Every grain engages the workpiece at the right cutting angle.

Cutting force is distributed evenly across the surface.

Sanding is smoother, faster, and more consistent.

The result? Lightning-fast sanding speeds with improved surface detail and minimized scratches. Shops can handle everything from coarse filler sanding to fine intermediate sanding with confidence and efficiency.

3. Anti-Blocking Super Coating

One of the biggest challenges in sanding automotive fillers and paints is clogging. Dust particles can quickly accumulate on the surface of standard abrasive paper, reducing its cutting ability and shortening its lifespan.

Golden Abrasives purple ceramic disc solves this problem with a specialized anti-clogging coating. This coating offers:

Enhanced heat dissipation: Preventing overheating during high-speed sanding.

Dust resistance: Reducing the adhesion of dust particles to the abrasive surface.

Extended product life: Maintaining cutting efficiency over longer use.

For technicians, this means fewer disc changes, less downtime, and lower consumable costs.

4. Cyclone Hole Distribution for Dust Extraction

Dust management is critical not only for surface quality but also for worker health and shop cleanliness. Golden Abrasives purple ceramic disc features hundreds of evenly distributed extraction holes designed in a cyclone pattern.

This innovative design:

Creates vortex airflow as the disc rotates.

Efficiently channels dust into the vacuum system.

Prevents dust from re-settling on the workpiece, which reduces secondary scratches.

Improves visibility during sanding, making it easier to achieve consistent results.

Compared to traditional single-hole discs, the cyclone pattern dramatically increases dust removal efficiency, contributing to both quality and safety.

5. Wide Range of Grit Options

Golden Abrasives purple ceramic disc is available in a full spectrum of grit sizes, ranging from 80+ to 800. This versatility allows technicians to use the same product line across multiple sanding stages:

Coarse sanding (80–120 grit): Removing paint, rust, or thick filler layers.

Intermediate sanding (180–320 grit): Leveling body filler and preparing surfaces for primer.

Fine sanding (400–800 grit): Finishing primer and ensuring surfaces are ready for paint application.

This wide grit availability makes the purple ceramic disc a one-stop solution for nearly all stages of automotive surface preparation.

Purple Ceramic Disc Practical Benefits for Auto Refinishing

So, what do these technical features mean in practical terms for repair shops? Let’s break it down.

Higher Efficiency

One of the biggest challenges in auto body and paint repair is the amount of time spent on sanding. Traditional wet sanding methods are not only slow but also inconsistent. The purple ceramic disc changes this by delivering sharp, precise cutting action thanks to its precision-shaped ceramic grains. These grains stay sharp longer, which means each pass removes more material with less effort. In practical terms, technicians can finish coarse sanding, filler leveling, or primer smoothing in much less time. For repair shops, this translates directly into faster job completion, more vehicles serviced per week, and higher overall productivity.

Improved Surface Quality

Quality is just as important as speed in refinishing. A poorly prepared surface will compromise paint adhesion and lead to visible defects after spraying. With the purple ceramic disc, consistent grain alignment ensures that each cut is uniform, avoiding uneven scratches or deep grooves. Combined with its advanced cyclone dust extraction, the sanding surface remains cleaner and more visible throughout the process. This results in smoother finishes that provide a perfect foundation for paint application. By using purple ceramic disc abrasives, shops can achieve higher-quality repairs that enhance customer satisfaction and reduce costly rework.

Cost Savings

Consumable costs are often overlooked, but for busy body shops, sandpaper replacement and rework expenses add up quickly. The purple ceramic disc offers extended service life due to its durable ceramic grains and anti-clogging coating. Fewer disc changes mean less downtime, while reduced clogging ensures consistent cutting performance over longer periods. Additionally, the improved efficiency of purple ceramic discs lowers labor costs because technicians can complete sanding tasks more quickly. When combined, these savings significantly reduce the total cost of operation, giving repair shops an edge in competitive markets.

Health & Safety

Worker safety is a critical concern in modern repair facilities. Sanding generates fine dust particles that can harm respiratory health if not properly managed. The purple ceramic disc addresses this with its cyclone hole distribution, which maximizes dust extraction efficiency. As the disc rotates, dust is directed into the vacuum system instead of lingering in the air or settling on surfaces. This not only protects technicians from prolonged dust exposure but also creates a cleaner, safer working environment. A healthier workforce is also a more productive workforce, and purple ceramic disc technology supports that goal.

Environmental Benefits

Sustainability is becoming increasingly important in the automotive repair industry. Traditional wet sanding generates large volumes of contaminated wastewater that must be collected and treated, adding to both costs and environmental impact. By switching to dry sanding with the purple ceramic disc, shops can completely eliminate wastewater pollution. In addition, the extended lifespan of these discs means fewer consumables are used and discarded, reducing overall waste. For repair shops committed to green practices, adopting purple ceramic disc sanding technology demonstrates responsibility to both customers and the environment, while also aligning with modern sustainability standards.

Case Study: Transition from Wet Sanding to Purple Ceramic Disc

A mid-sized body shop previously relied on manual wet sanding for filler and primer preparation. The process was labor-intensive, produced inconsistent results, and required wastewater management.

After switching to the purple ceramic disc:

Sanding time was reduced by nearly 40%.

Disc consumption dropped by 30% due to extended lifespan.

Surface quality improved, resulting in fewer paint defects and reworks.

The shop reported increased throughput, enabling it to handle more jobs per week.

This case demonstrates how investing in advanced abrasives can directly improve efficiency and profitability.

Why the Purple Ceramic Disc Is the Future of Auto Body Sanding

The purple ceramic disc is not just another sandpaper—it is a comprehensive solution tailored to the modern needs of automotive refinishing. By combining cutting-edge abrasive technology, anti-clogging coatings, cyclone dust extraction, and a full grit range, it addresses the key challenges faced by repair shops today.

For small and medium-sized auto repair businesses, adopting the purple ceramic disc can level the playing field against larger competitors. It empowers shops to deliver faster service, higher quality, and better profitability, all while promoting a cleaner and safer working environment.

Conclusion

In auto body and paint repair, time is money. Sanding, which consumes up to 30% of repair time, is the area with the greatest potential for improvement. Golden Abrasives purple ceramic disc offers exactly that improvement—faster cutting, longer life, superior dust control, and unmatched versatility.

For shops looking to enhance productivity, reduce costs, and deliver flawless paint finishes, the purple ceramic disc is the ultimate solution. By investing in this advanced abrasive technology, auto repair businesses can say goodbye to inefficiency and hello to higher profits, better quality, and a more sustainable future.

https://www.goldenabrasives.com/purple-ceramic-sandpaper.html

http://www.goldenabrasives.com

China Golden Abrasives -

AuthorPosts

- You must be logged in to reply to this topic.