- This topic is empty.

-

AuthorPosts

-

2025-10-13 at 2:50 pm #10861

1. Introduction: Understanding the Importance of Subframes

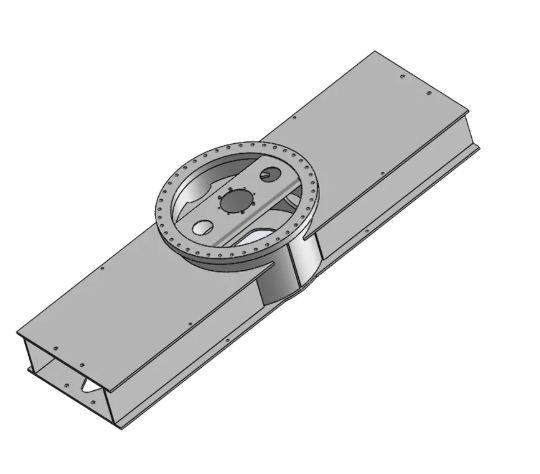

In the construction and energy sectors, subframes are critical components that provide structural support and stability for heavy machinery. A well-designed and precisely manufactured subframe ensures the durability and efficiency of equipment used in challenging environments. Hengli, with over 20 years of experience and state-of-the-art technology, delivers high-quality subframe manufacturing services tailored specifically for construction and energy equipment applications.

2. Overview of Subframe Manufacturing Process

Manufacturing subframes involves several complex processes that require precision and expertise. At Hengli, we begin with a thorough analysis of client requirements, followed by custom design using advanced CAD software. This ensures each subframe meets the specific needs of its application. The main manufacturing steps include:

-

Cutting: Using laser, flame, and plasma cutting machines to process high-quality carbon steel, alloy steel, stainless steel, or aluminum plates.

-

Bending and Forming: CNC and robotic bending machines shape the metal plates with high precision.

-

Welding: Certified welders and robotic systems join the components with advanced techniques such as MAG, TIG, laser welding, ensuring strength and durability.

-

Machining: CNC machining centers perform drilling, milling, and finishing to achieve tight tolerances and smooth surfaces.

-

Surface Treatment: Powder coating, painting, galvanizing, and other finishing techniques protect subframes from corrosion and wear.

3. Materials Used in Subframe Manufacturing

Material selection is crucial for producing reliable subframes. Hengli offers a variety of materials depending on the application, including:

-

Carbon Steel: Known for strength and affordability.

-

Alloy Steel: Offers enhanced strength and resistance.

-

Stainless Steel: Provides excellent corrosion resistance.

-

High-Strength Steel: Ideal for heavy-duty applications.

-

Aluminum: Lightweight and corrosion-resistant.

Choosing the right material balances durability, weight, and cost for each client’s unique needs.

4. Quality Control and Certification

Hengli places great emphasis on quality assurance throughout the manufacturing process. The company adheres to international standards, including ISO 9001:2015, and undergoes regular audits by Bureau Veritas. Quality control includes:

-

Dimensional inspections to maintain tolerances between +/-0.05 to 0.15mm.

-

Mechanical testing to verify strength and durability.

-

Visual and non-destructive testing to detect welding defects.

These steps guarantee that every subframe performs reliably under extreme conditions typical in construction and energy industries.

5. Customization and Technical Support

No two projects are the same. Hengli offers customized subframe manufacturing services tailored to customer drawings and specifications. Beyond manufacturing, Hengli provides on-site technical support, inspection, and problem-solving resources to ensure seamless integration of subframes into the client’s equipment.

This customer-centric approach helps clients reduce downtime and optimize equipment performance.

6. Advantages of Partnering with Hengli

Choosing Hengli for subframe manufacturing means partnering with an industry leader that offers:

-

Over 120,000 tons of annual steel processing capacity.

-

Modern equipment including 12 laser cutters, 14 flame/plasma cutters, multiple CNC bending and machining centers.

-

Skilled workforce of more than 1,600 employees including certified welders.

-

Comprehensive service chain from raw material procurement to logistics.

-

Competitive pricing and short lead times.

Our global reach extends to markets in North America, Europe, Asia, and Oceania, where our reputation for quality and reliability continues to grow.

7. Conclusion: Excellence in Subframe Manufacturing for Construction and Energy

The ultimate guide to subframe manufacturing for construction and energy equipment highlights the critical role subframes play in machine performance and longevity. Hengli’s expertise in precision manufacturing, strict quality control, and customer-focused customization ensures we deliver products that exceed industry standards. Whether you need subframes for construction machinery, energy equipment, or specialized vehicles, Hengli is your trusted partner for durable, high-quality solutions.

http://www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.