- This topic is empty.

-

AuthorPosts

-

2025-02-12 at 6:29 pm #8668

Sintered samarium cobalt (SmCo) magnets are a type of rare-earth magnet that have gained significant attention in various industries due to their exceptional magnetic properties and performance in demanding environments. This article aims to provide an in-depth understanding of the properties, manufacturing processes, and applications of sintered samarium cobalt magnets.

What are Sintered Samarium Cobalt Magnets?

Sintered samarium cobalt magnets are made from a combination of samarium and cobalt, which are rare-earth elements. These magnets are produced through a sintering process, where powdered materials are compacted and heated to form a solid mass without melting. This process enhances the magnetic properties of the material, making sintered SmCo magnets some of the most powerful permanent magnets available.

There are two primary grades of samarium cobalt magnets: SmCo 1:5 and SmCo 2:17. The numbers represent the ratio of samarium to cobalt in the alloy, with SmCo 2:17 typically offering higher magnetic performance compared to SmCo 1:5.

Key Properties of Sintered Samarium Cobalt Magnets

High Magnetic Performance: Sintered SmCo magnets exhibit high remanence (the magnetization remaining after an external magnetic field is removed), high coercivity (the ability to withstand demagnetization), and a high magnetic energy product (the maximum magnetic energy density).

Temperature Stability: One of the features of sintered samarium cobalt magnets is their ability to operate in extreme temperatures. They can function effectively at temperatures up to 350 °C, making them suitable for applications in high-temperature environments.

Corrosion Resistance: Unlike other types of magnets, sintered SmCo magnets have excellent corrosion resistance, which allows them to be used in harsh environments without the need for additional protective coatings.

Low Temperature Coefficient: Sintered samarium cobalt magnets have a low temperature coefficient, typically ranging from -0.03% to -0.05% per °C. This means their magnetic properties remain relatively stable across a wide temperature range.

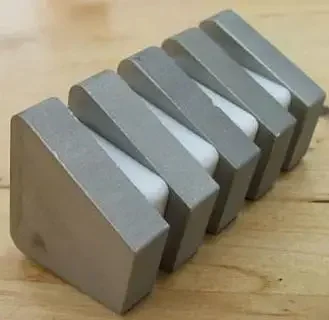

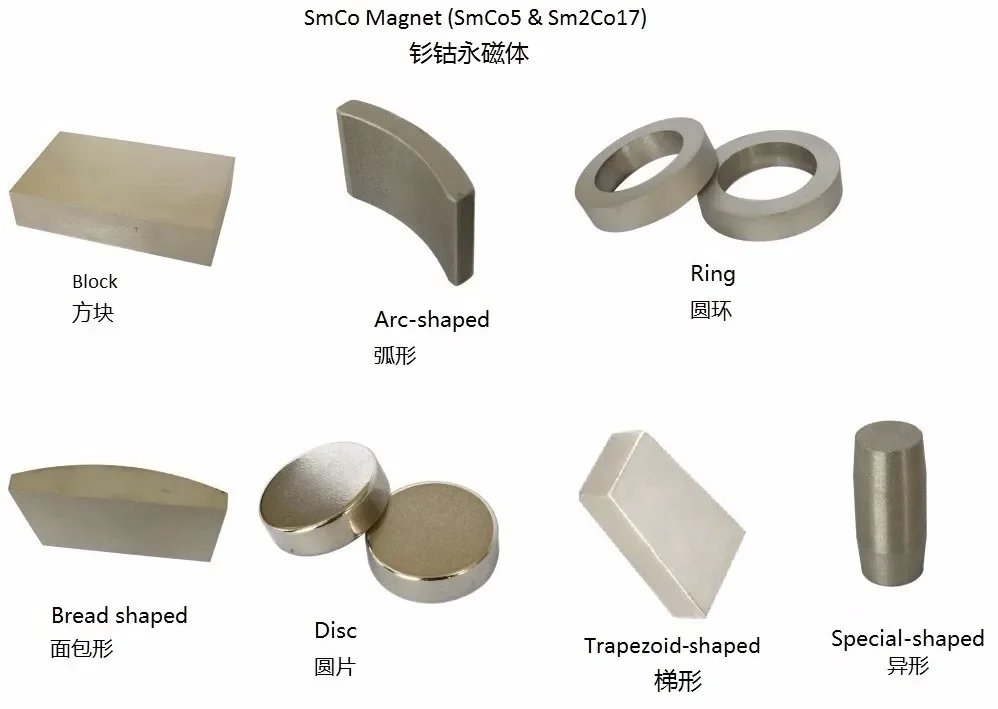

Versatile Shapes and Sizes: These magnets can be manufactured in various shapes and sizes, making them adaptable for different applications, from small electronic devices to large industrial machinery.

Manufacturing Process of Sintered Samarium Cobalt Magnets

The manufacturing of sintered samarium cobalt magnets involves several key steps:

Material Preparation: The first step is to prepare the raw materials, which include samarium and cobalt powders. These powders are mixed in the desired ratio to create the alloy.

Compaction: The mixed powders are then compacted into a mold under high pressure. This process forms a green body, which retains the shape of the mold.

Sintering: The green body is heated in a vacuum or inert atmosphere at high temperatures (typically between 1000 °C and 1300 °C). During sintering, the powders bond together, resulting in a dense and solid magnet.

Machining: After sintering, the magnets may require machining to achieve precise dimensions and surface finishes. This step is crucial for applications where tight tolerances are necessary.

Magnetization: Finally, the magnets are magnetized using a strong external magnetic field, which aligns the magnetic domains within the material, resulting in a powerful permanent magnet.

Applications of Sintered Samarium Cobalt Magnets

Sintered samarium cobalt magnets are utilized in a wide range of applications across various industries due to their unique properties. Some notable applications include:

1. Aerospace Industry

In the aerospace sector, sintered SmCo magnets are used in various components, including actuators, sensors, and motors. Their ability to withstand high temperatures and harsh conditions makes them ideal for applications in aircraft and spacecraft.

2. Automotive Industry

The automotive industry employs sintered samarium cobalt magnets in electric motors, fuel pumps, and various electronic devices. Their compact size and high performance contribute to the efficiency and reliability of modern vehicles.

3. Industrial Machinery

Sintered SmCo magnets are widely used in industrial machinery, including robotics, conveyor systems, and automation equipment. Their durability and resistance to demagnetization ensure consistent performance in demanding industrial environments.

4. Medical Devices

In the medical field, sintered samarium cobalt magnets are found in imaging equipment, such as MRI machines, and in various surgical instruments. Their high magnetic performance and stability make them essential for precise medical applications.

5. Consumer Electronics

Sintered SmCo magnets are also used in consumer electronics, including speakers, headphones, and hard drives. Their compact size and powerful magnetic properties enhance the performance of these devices.

6. Military Applications

The military sector utilizes sintered samarium cobalt magnets in various applications, including guidance systems, communication devices, and sensors. Their reliability and performance in extreme conditions are critical for military operations.

Conclusion

Sintered samarium cobalt magnets are a vital component in many modern technologies, offering exceptional magnetic properties and performance in challenging environments. Their unique characteristics, including high temperature stability, corrosion resistance, and versatility, make them indispensable in industries ranging from aerospace to consumer electronics. As technology continues to advance, the demand for high-performance magnets like sintered SmCo will likely increase, driving further innovation and applications in various fields. Understanding these magnets' properties and applications is essential for engineers and manufacturers looking to leverage their capabilities in future designs.

ABM Magnetics Co. Ltd. specialized in the manufacturing and providing engineering solution for magnetic material and assembly. Most of our engineers worked in this field with more than ten year's experiences are available here to provide customer more economical, quick and professional services.

Welcome to contact us if you want to know more about sintered samarium cobalt magnets details.

E-mail:martin@abm-magnetics.com

http://www.abm-magnetics.com

ABM Magnetics Co. Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.