- This topic is empty.

-

AuthorPosts

-

2025-10-31 at 3:20 pm #11040

The manufacturing world increasingly depends on extrusion technologies to create products with precision, consistency, and durability. Among these technologies, the plastic profile extrusion line stands out as a reliable solution for producing complex shapes such as window frames, pipes, decorative trims, and industrial channels. This advanced system allows manufacturers to achieve large-scale production while maintaining strict quality control. In a global market where efficiency, customization, and cost-effectiveness are critical, investing in a well-designed extrusion line has become a necessity rather than an option.

What is a Plastic Profile Extrusion Line?

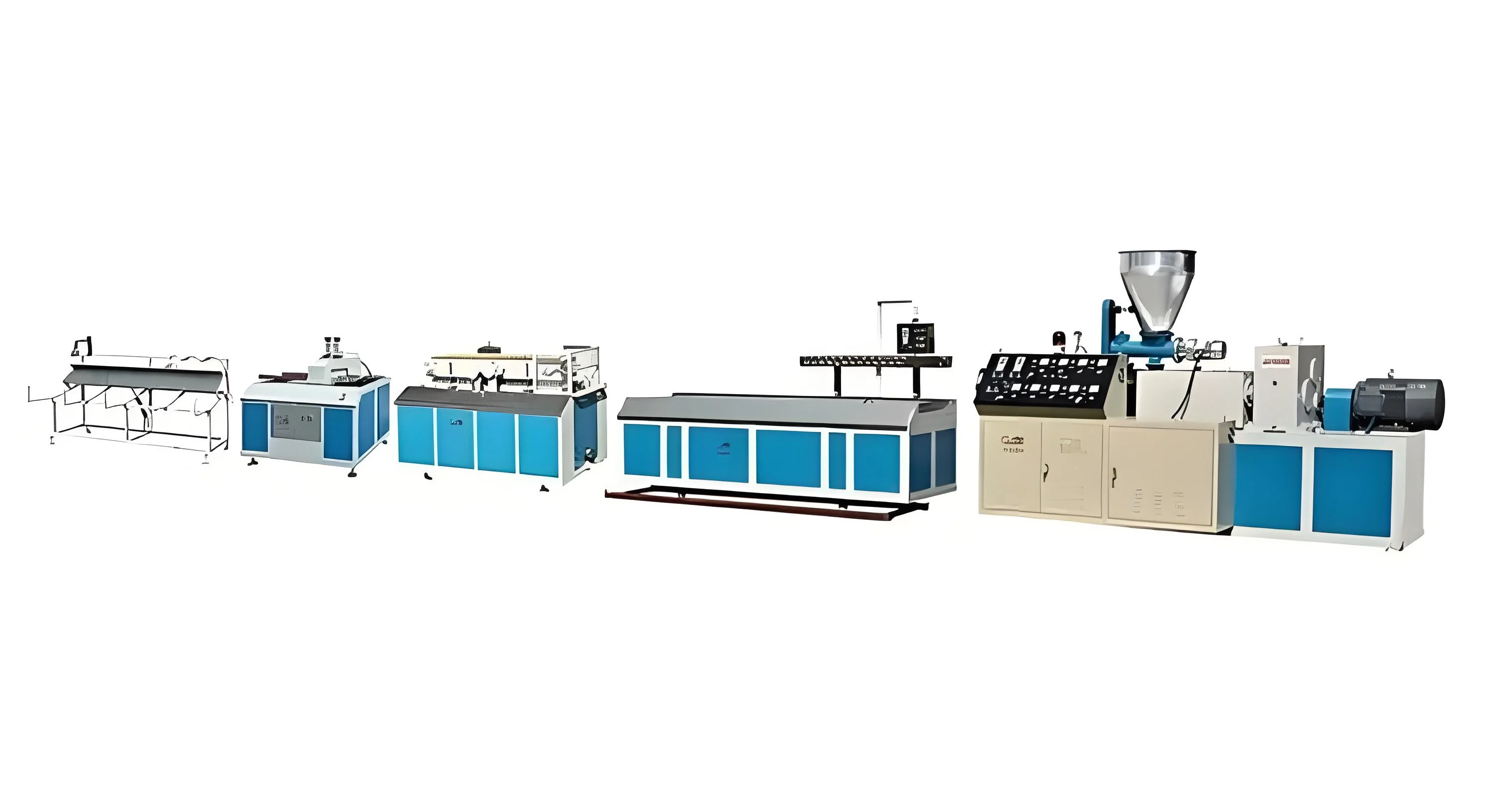

A plastic profile extrusion line is a complete manufacturing system designed to process raw plastic materials into continuous profiles with uniform cross-sections. The process involves melting polymer resins, shaping them through a die, and cooling them into a finished form. Depending on the design, the line can produce hollow, solid, or multi-layered profiles used across a wide range of industries.

The system typically includes several interconnected components such as the extruder, die head, calibration system, cooling unit, haul-off, and cutting device. Each section plays a specific role in ensuring that the final product meets dimensional accuracy and performance requirements.

Advantages of Using a Plastic Profile Extrusion Line

A plastic profile extrusion line offers a modern, efficient, and precise solution for producing a wide range of plastic profiles used in construction, automotive, electrical, and consumer goods industries. Compared to traditional molding or machining methods, this continuous manufacturing process provides superior control, efficiency, and material savings. Below are the key advantages of implementing a plastic profile extrusion line in production.

High Precision and Consistency

One of the most notable advantages of a plastic profile extrusion line is its ability to deliver exceptional dimensional accuracy and uniformity across long production runs. Unlike batch-based molding methods, extrusion operates continuously, producing profiles with consistent cross-sections and surface quality.

Advanced control systems—such as automatic temperature regulation, closed-loop pressure feedback, and laser-based dimensional monitoring—ensure repeatable results from start to finish. This high precision minimizes scrap generation and material loss, while maintaining tight tolerances that meet demanding industry standards. As a result, manufacturers using a plastic profile extrusion line benefit from stable quality, improved product appearance, and reduced rework costs.

Cost-Effective Production

A well-optimized plastic profile extrusion line significantly lowers overall manufacturing costs by enabling continuous and automated operation. Because extrusion minimizes downtime between production cycles, manufacturers can achieve high throughput with minimal labor intervention.

Energy-efficient extruders, smart cooling systems, and advanced screw designs also contribute to lower power consumption and faster cycle times. Additionally, material waste is minimized since the process utilizes almost all feedstock in the final product. Over time, these advantages translate into a lower cost per unit, making the plastic profile extrusion line a highly economical solution for both large-scale and specialized production needs.

Customization and Flexibility

Flexibility is another defining feature of the plastic profile extrusion line. By simply changing the extrusion die or adjusting process parameters—such as temperature, screw speed, or cooling rate—manufacturers can easily produce profiles of different shapes, dimensions, or material blends.

This adaptability allows companies to respond quickly to changing customer requirements or market trends. Whether producing rigid window frames, flexible sealing strips, or complex co-extruded profiles, the plastic profile extrusion line offers unmatched versatility. It supports both mass production for standardized products and small-batch custom runs for specialized applications, ensuring a competitive edge in dynamic markets.

Enhanced Material Utilization

A plastic profile extrusion line enables direct integration of additives and modifiers during the extrusion process. UV stabilizers, flame retardants, plasticizers, and colorants can be uniformly blended into the polymer melt, ensuring consistent performance and appearance throughout the profile.

This inline compounding eliminates the need for post-processing treatments or additional coating steps, saving both time and resources. Furthermore, precise material dosing and controlled mixing enhance the overall mechanical and thermal properties of the finished profiles. By maximizing material utilization and process efficiency, the plastic profile extrusion line supports sustainable manufacturing practices and reduces production waste.

The plastic profile extrusion line is more than just a machine—it is a complete solution that empowers manufacturers to deliver precision, efficiency, and innovation. From construction to automotive, and from household products to industrial applications, extrusion technology continues to shape countless industries. By choosing the right materials, implementing advanced automation, and maintaining rigorous quality control, businesses can fully unlock the potential of their extrusion line. In a world driven by efficiency and customization, the plastic profile extrusion line remains an indispensable tool for sustainable growth and competitive advantage.

https://www.xingdapm.com/Unlocking-Efficiency-and-Quality-with-a-Plastic-Profile-Extrusion-Line.html

https://www.xingdapm.com/plastic-profile-extrusion-line.html

http://www.xingdapm.com

Zhangjiagang Xingda Machinery Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.