- This topic is empty.

-

AuthorPosts

-

2025-07-21 at 9:45 am #10135

In today’s fast-paced manufacturing and design industries, precision and efficiency are paramount. Whether you are producing packaging, electronics components, automotive parts, or custom labels, the die cutting processing service plays a crucial role in shaping your product’s final quality and functionality.

If you’re new to this process or want to understand how to leverage die cutting for your business, this comprehensive guide is for you. We’ll cover what die cutting is, how it works, its benefits, and why partnering with an experienced provider like Dongguan Xuanjie Electronic Products Co., Ltd. can elevate your production.

What Is Die Cutting Processing Service?

Die cutting is a manufacturing process that uses a specialized die (a shaped blade or mold) to cut, shape, or perforate materials with high precision. The materials can range from paper, cardboard, plastics, foils, and textiles to specialized tapes and films.

A die cutting processing service refers to outsourcing this precise cutting operation to a professional provider equipped with advanced machinery and expertise. This service is widely used across industries such as packaging, electronics, automotive, textiles, and advertising.

How Does Die Cutting Work?

The die cutting process involves:

-

Designing the Die: A custom die is created according to the specific shape and dimensions needed.

-

Material Preparation: The material to be cut—such as adhesive tapes, plastic films, or paperboard—is fed into the die cutting machine.

-

Cutting: The machine presses the die into the material, cutting it cleanly and precisely without damaging surrounding areas.

-

Ejection and Finishing: The cut parts are separated and may undergo additional finishing processes such as embossing or laminating.

With modern automation, die cutting achieves high speed and consistent accuracy even for complex shapes and delicate materials.

Benefits of Die Cutting Processing Service

-

Precision and Consistency: Guarantees uniform cuts across large volumes, essential for quality control.

-

Cost Efficiency: Reduces material waste and labor costs through automated production.

-

Customization: Supports complex and custom shapes for unique product designs.

-

Versatility: Works with a wide range of materials, including specialized tapes and films.

-

Speed: Accelerates production timelines with high-speed automated equipment.

Why Partner with Dongguan Xuanjie Electronic Products Co., Ltd.?

When it comes to die cutting services, particularly in electronic and industrial applications, Dongguan Xuanjie Electronic Products Co., Ltd. stands out as a reliable partner.

The company specializes in the research and manufacturing of:

-

Black double-sided adhesive tapes

-

Black and white double-sided tapes

-

Repair tapes and specialty adhesive products

With state-of-the-art fully automated production lines and multiple compliance testing instruments, Dongguan Xuanjie ensures that every batch meets rigorous quality standards. Their expertise in specialty adhesive tapes makes them uniquely qualified to provide die cutting services for tapes used in electronics, electrical insulation, and other demanding applications.

Choosing Dongguan Xuanjie means:

-

Access to tailored die cutting solutions for adhesive tapes and other materials

-

Consistent high quality supported by advanced quality control systems

-

Flexibility to meet diverse and customized production needs

Applications of Die Cutting Services in Various Industries

-

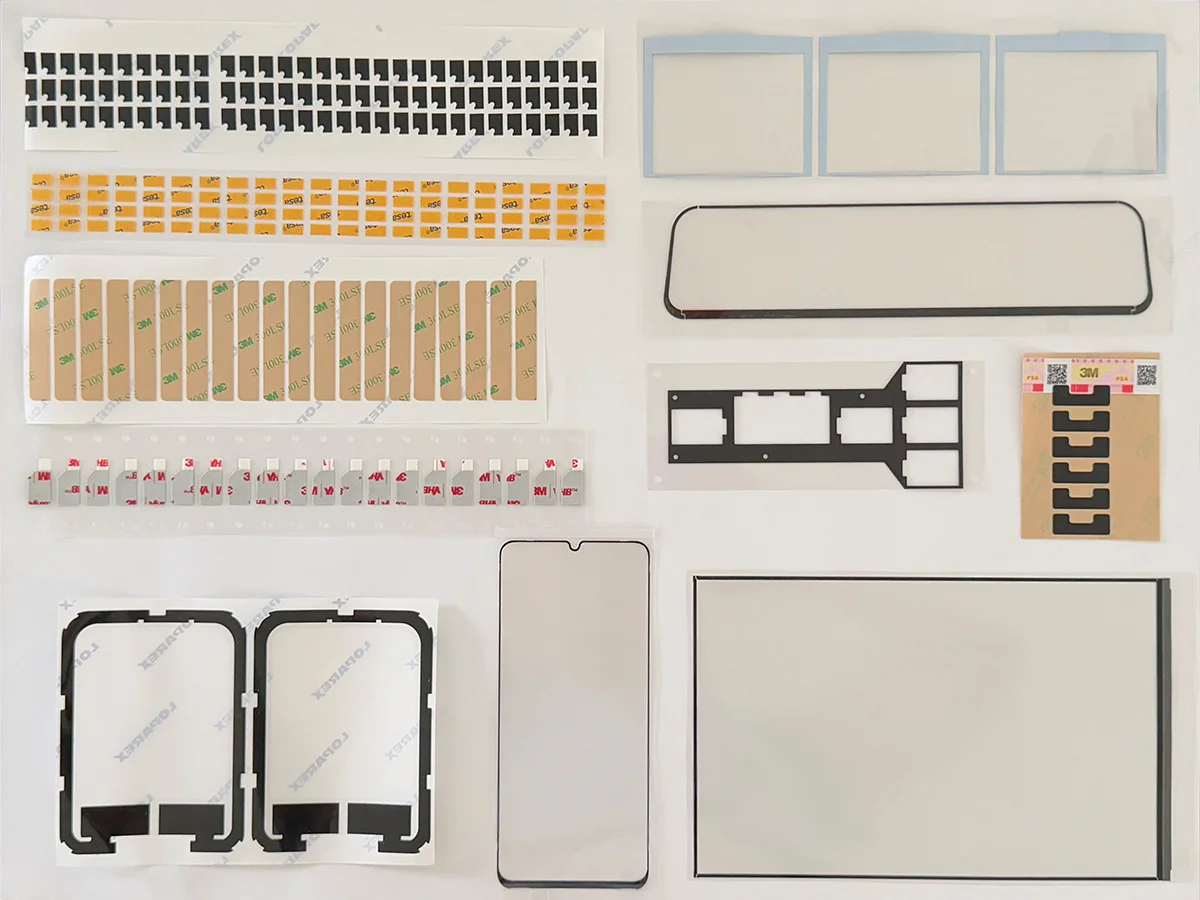

Electronics: Precise cutting of insulation tapes, gaskets, and protective films.

-

Packaging: Custom-shaped boxes, labels, and inserts.

-

Automotive: Cutting of sealing strips, decals, and noise dampening materials.

-

Medical: Production of adhesive patches, bandages, and sterile packaging.

-

Advertising: Die cut stickers, decals, and promotional materials.

Final Thoughts

The die cutting processing service is an indispensable part of modern manufacturing and design. It enables companies to achieve precision, reduce waste, and speed up production without compromising quality.

For businesses relying on specialized materials like adhesive tapes, partnering with a professional and experienced provider such as Dongguan Xuanjie Electronic Products Co., Ltd. can make all the difference — delivering customized solutions that meet stringent industrial requirements.

http://www.dgxjdz.cn

Dongguan Xuanjie Electronic Products Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.